There are many ways of reducing aftersales costs. Starting with repair-friendly and low-fault design, through fault detection and rectification, active recourse management, to digitalized processes for maintenance and in the repair shop, to name but a few. In addition to attending to these matters, IT equipment should also be included in the optimization. Clear structures and modern tools offer opportunities for efficiency gains that are not so obvious, even though they have the potential to materially reduce costs.

Almost inevitably, an IT system landscape that has existed for many years will deviate more and more from the original concept. "Legacy structures" is a frequently used euphemism for a certain amount of uncontrolled growth. One aspect, for example, is "shadow IT": Applications that are purchased without the knowledge of the IT department because someone has decided that these are more useful than those the administrators have allowed. The – at least perceived – added value is countered by potential problems such as a lack of security for corporate data, incompatible data formats, and uncontrollable data versions and resources, which have a negative impact on efficiency.

Another issue are the interfaces (APIs), frameworks and libraries used. In this context, "legacy structures" generally means that dependencies on and interactions of complexly linked systems are no longer manageable. Concerns about service IT instabilities, perhaps even failures, lead to outdated systems continuing to be operated and kept up and running, in some cases involving a great deal of manual effort. This is harmful on two counts: firstly because of the high cost of IT administration work, and secondly because on the user side, the support provided by modern tools cannot be used. It is therefore vital that the quality of the existing systems is regularly checked and that, where necessary, thought is given to the reorganization of the IT system landscape. The concept and selection of a follow-on solution must, however, be well prepared. There are three key aspects here.

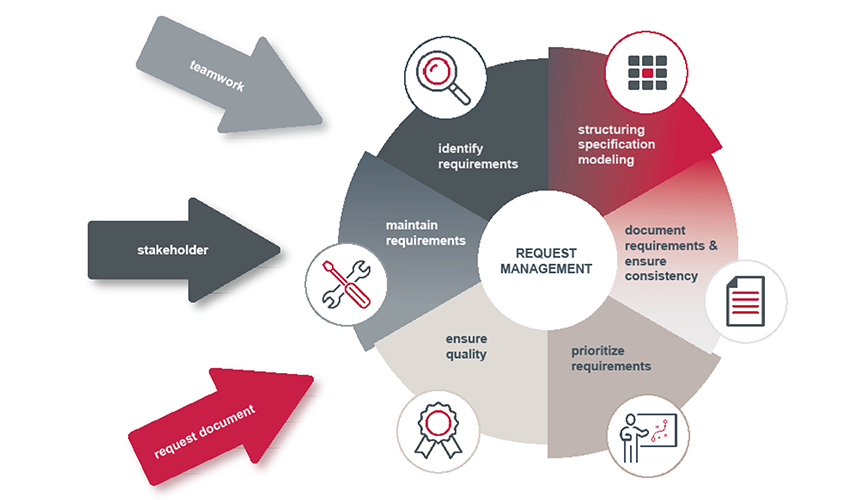

1. Identifying requirements

The first priority with a project of this type is a structured requirements management, to ensure that the software requirements defined are met. This involves not only internal requirements and needs, but also, from the very beginning, those of external stakeholders. These must be collected, structured and documented at an early stage. This is the first step to the success of such a project. If the work in this preparatory phase is not done carefully, there is a risk of uncontrolled additional work and costs in the further course of the project: in the area of software development, for example. Good, clearly defined requirements, on the other hand, make it possible to take the right conceptual path from the outset. This has a positive effect on the duration of the project. Fewer unforeseen changes of direction within projects and reduced time pressure create room for better code quality and therefore fewer problems in the long term when it comes to the maintenance and upgrading of systems.

2. Making and implementing strategic decisions

In a large system landscape, one problem is that there is often no overview of all the systems used and their range of functions. Different organizational units each rely on their own tools, creating integration problems and slowing down the ongoing modernization of the IT landscape. This development is usually based not on strategic considerations, but on independent (historical) decision-making processes. The alternative is an end-to-end strategy for a system landscape that enables more standardized software applications, more consistent tool chains, and more compact workflows.

After a suitable strategy identifying system and business requirements has been defined, and the existing EAM (Enterprise Architecture Management) strategy has been analyzed, a number of decisions need to be made: on standards and guidelines, for example, or the method framework, and process architecture. The next step is to prepare for implementation. Among other things, this involves the consolidation of all data and systems, and calls for comprehensive change management and streamlined project management.

3. Searching for suitable suppliers

In the IT environment, selecting the right suppliers can save real money. As with vehicle components, experience and well established mutual trust play a decisive role here. Companies often have a large number of suppliers and partnerships which have evolved over the years. The collaboration is not always profitable. This is often not something the parties involved are even aware of, as there are many inefficiencies in the process that are not taken into account - and in the end lead to unnecessarily high costs.

With a selected supplier base, tasks can be centralized and the relationship made more efficient, as time and cost involved in supplier management are reduced. Allowing a supplier to have a monopoly is something to avoid at all costs. However, regular evaluations and audits of the suppliers used are essential. Product specifications in which clearly defined requirements are set out are the basis for obtaining concrete quotations. If the foundations are not clearly laid, there is a risk of higher costs and of an enormous increase in the administrative overheads.

Competencies needed all from a single source

Bringing about a modern and efficient IT landscape which will in all ways provide optimum support for aftersales is a complex undertaking. On the one hand, this calls for different competencies, while on the other these competencies need to work together to create a system landscape which ultimately is free of disruptions.

With its wide range of services and experienced digitalization experts, EDAG Engineering can score points here. This enables the service provider to help identify and prioritize department-specific and hidden requirements, evaluate the appropriate tools, and set up the requirements plan. Likewise, the EDAG specialists can design an all-round strategy for the system landscape or system architecture, develop plans for consolidating all data and systems, and manage the rollout of the new hardware and software. And last but not least, EDAG offers assistance with the development of a new partner strategy, with market research for example, or supplier audits, the definition of purchasing guidelines or the development of strategies for continuously tracking supplier quality.

Do you also see the need to take a critical look at your IT system landscape? Then contact Mona Dorn, Project Manager in Aftersales at EDAG Engineering, to find out what options are available and what priorities have proved valuable. Or download our comprehensive "EDAG Aftersales Cost Guide" here. This navigator for greater efficiency and more satisfied customers highlights various ways of optimizing aftersales. It provides detailed tips on how to successfully modernize your IT environment.