Although from a statistical point of view we are living in the safest age to date, growing religious, ethnic and resource-related conflicts worldwide and the activities of various terrorist groups mean that people are experiencing an increased need for protection and security in all areas of life.

We, EDAG CAE & Safety, are your competent partner in the simulation-assisted development of armoured civilian and military vehicles, protective equipment, laminated safety glazing, and all kinds of special protection solutions with IMPETUS Afea Solver. We can draw on almost 30 years' experience in the development of high-security vehicles, and, by means of simulation-assisted development, every day make an important contribution to protecting life and property.

Providing all-round support for your development project, and taking initial concept studies as our basis, we work with you to develop functional protection solutions specially tailored to your requirements, and see your development process through to the successful certification of your product.

In order to protect civilians travelling on the roads from attack, the OEMs have since the late 1920s been developing high-security vehicles which, on account of the increase in demand, are offered in diverse resistance classes.

Both as experts in complete vehicle development and as a service provider for international automotive corporations, we know that, for market requirements to be met, the development cycles for these vehicles need to become shorter and shorter. Due to the resulting intensification of cost and time pressure, increasing use is being made of test simulation in this field of development, as a means of supplementing or to some extent replacing cost-intensive and often time-critical physical tests on manually constructed prototype vehicles.

A large number of firing and bombardment tests need to be carried out during the development of high-security vehicles or the armouring integrated in these, to enable the effects of structural modifications to be safely assessed. In the past, quite often the only way of doing this was to draw on estimates and empirical values from previous vehicle developments, as it was simply not possible to fully visualise exactly what would happen during an explosion or firing incident, and then subsequently derive the appropriate, precise measures.

Simulation: Understanding reality and making targeted changes

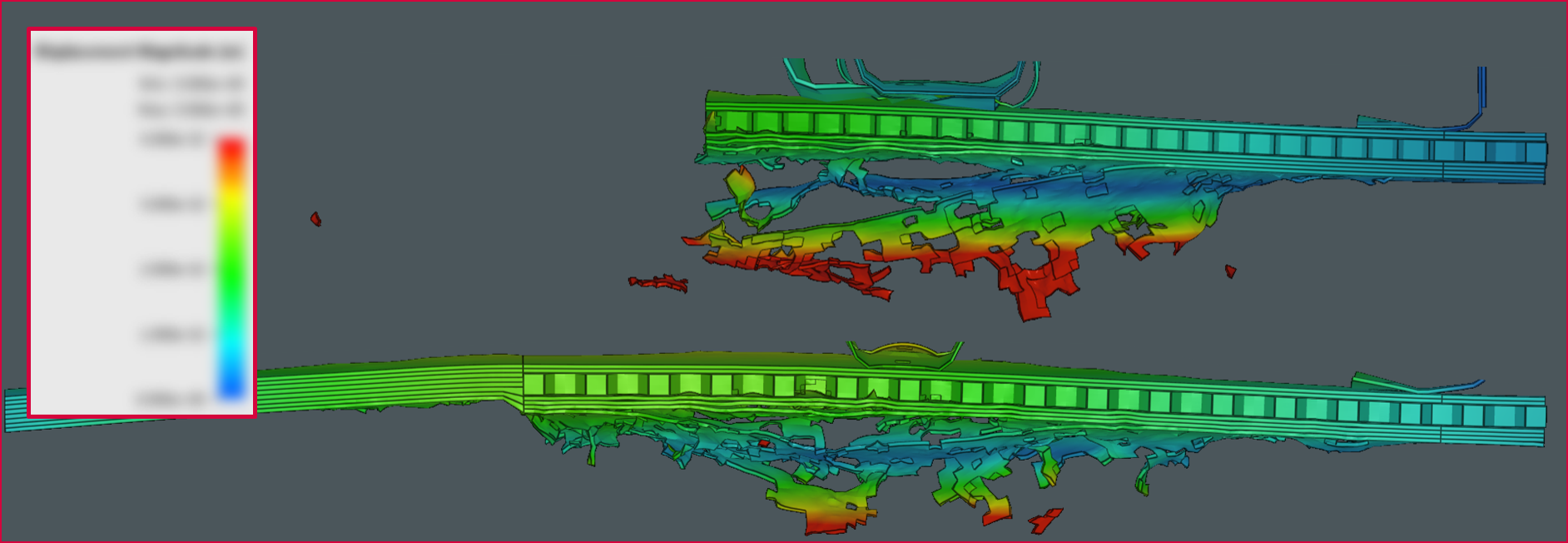

Sectional view of a blast test on the underbody of a high-security vehicle

Sectional view of a blast test on the underbody of a high-security vehicle

The use of the IMPETUS Afea Solver places us in a position to test various concepts in the early stages of development. The essential advantages of virtually assisted development lie in the early, well-founded assessment of the efficiency of the selected protection concept and in the ability of the model to adapt to a wide range of threatening scenarios and certification load cases.

Since 2021, the VPAM ERV version 3 has prescribed the use of a so-called biofidelic dummy, the "Primus Breakable® ", from the company: crashtest-service.com GmbH, to assess occupant loads.

Conventional crash test dummies, such as the "Hybrid III", which is used in STANAG 4569 to assess protected military vehicles, do not yet allow direct assessment of injuries, but instead record characteristic and direction-dependent force, moment or pressure curves. In addition, there is a risk of damaging or destroying the cost-intensive dummy equipped with measurement technology in the event of an unsuccessful certification attempt.

The "Primus Breakable® ", with its biofidelic behavior that imitates humans, addresses precisely this problem, as its damaging behavior is comparable to its anthropomorphic role model. Accordingly, the possible range of applications is extremely diverse and, in addition to the evaluation of protected vehicles, includes the development of body protection equipment such as bulletproof and stab-proof vests, helmets and EOD suits. The evaluation of the injuries to be expected in a person and their intensity is always carried out by means of a subsequent autopsy of the dummy.

IMPETUS simulation model of the biofidelic Primus Breakable (left) compared to the conventional Hybrid III crash test dummy (right)

Further information on this topic is available in our free webinar on VPAM ERV version 3 at:

Thanks to our involvement in the development of the simulation model of the "Primus Breakable® " for IMPETUS Afea, which was created in cooperation with crashtest-service.com GmbH and AFUS Forschungsgesellschaft, a suitable simulation model is now available to illustrate and validate the significant effects of impacts on occupants during the development phase of protected vehicles.

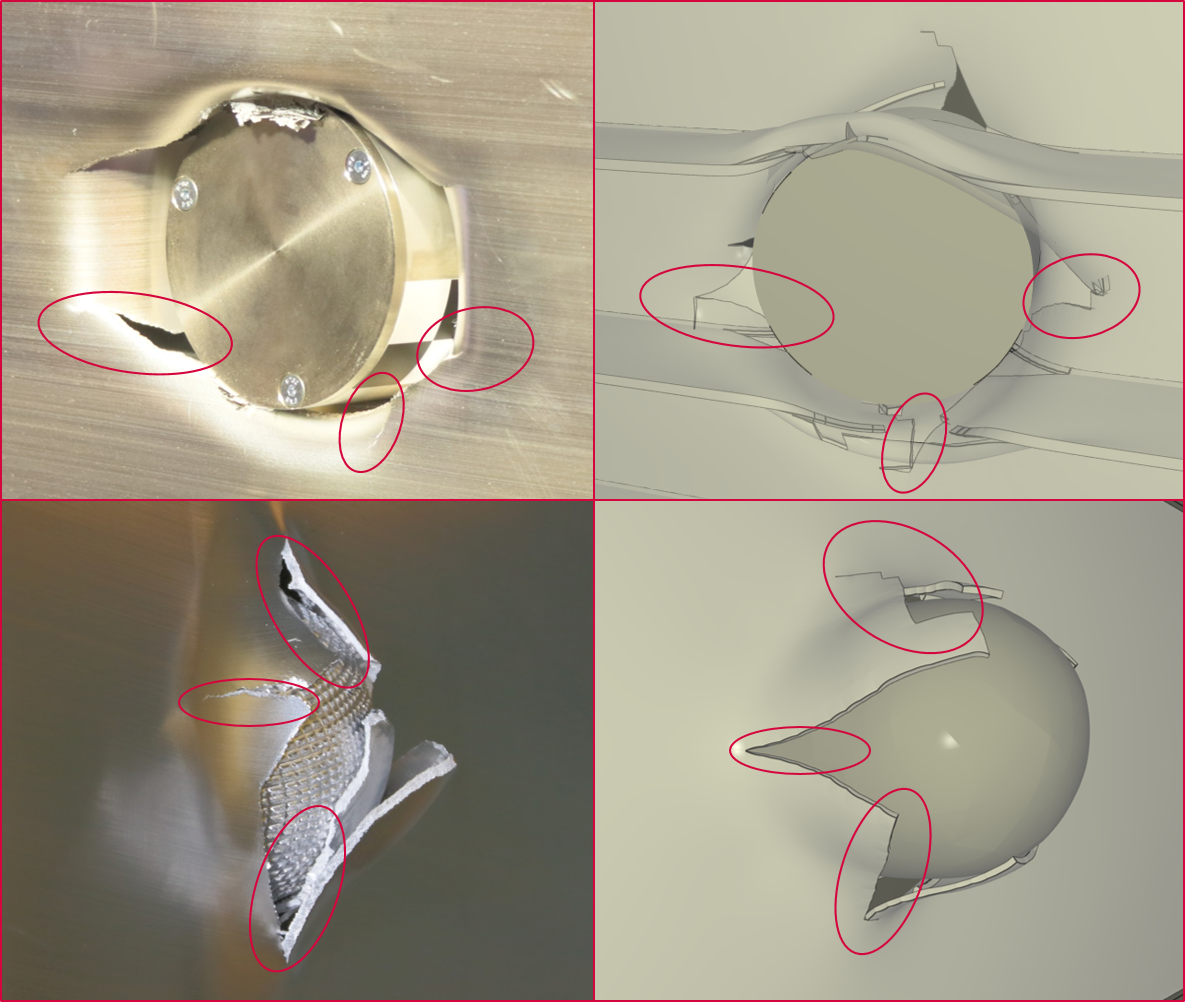

By carrying out detailed tests on critical areas, we are able to systematically determine possible weak points of components and systems, and can assess the residual protective effect by means of deliberately induced overload situations. This leads to a profound understanding of the various interactions that occur during blasting or ballistic impact, as a result of which strategic corrective action can then be taken to improve the protective system.

It goes without saying that, along with the expertise of our customers, the bundled know-how of additional EDAG departments also comes to bear at this point, enabling us to implement improvements arrived at by means of simulation in accordance with design guidelines and with the support of testing departments. This fully integrated, independent engineering concept enables us to offer our customers a wide-ranging portfolio of in-house development and validation services for high-security vehicle construction, personal protective equipment, safety glazing and other general protective systems.

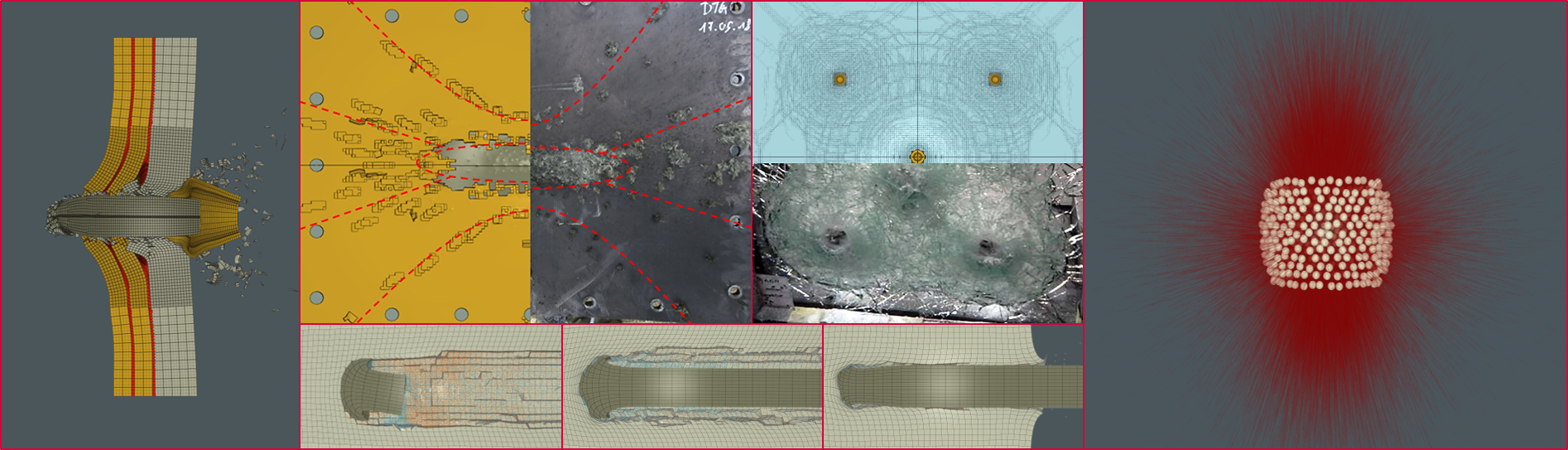

Variation of various detailed examinations

Variation of various detailed examinations

The potential range of customers is as diverse as the various feasible simulation tasks:

- Reconstruction of certification volumes

- Adaptable detailed investigations

- Systematic analysis of weak points

- Impact scenarios in structures and target ballistics

- Simulation reconstruction of attack scenarios

- Concept studies and parameter optimisation

- Simulation of physical tests

IMPETUS AFEA - VALIDATED SIMULATION BECOMES SIMULATED REALITY

For the simulation volumes described here, we use the IMPETUS Afea Solver, which was designed by IMPETUS Afea AS primarily for extremely non-linear, highly dynamic tasks. This explicit FE solver is particularly suitable for the simulated imaging of blasting and ballistic impact on structures, and therefore for the numerical imaging of large structural dynamic deformations under extreme stress conditions.

To do justice to our responsibility to protect our greatest asset - human life - we formulate corresponding quality objectives for the predictive quality of our simulations. Throughout, we are constantly aware of the importance of this type of simulation, and so are continually working on further optimising it, to prevent an emergency from ever becoming the test run.

Apart from a numerically extremely stable solver, this also calls for detailed material and damage models, that, even when high degrees of deformation and strain rates are involved, will supply reliable results and enable ductile and brittle materials to be recorded in equal measure. As well as being able to simulate impacts caused by solid objects, we can also show the structural effects of blast waves. As the simulative measurement of gases, fluids or granulates is also possible, the effect of a buried mine, for instance, can be simulated by means of structure-particle interaction. For this reason, using conventional crash solvers to calculate these these highly dynamic processes is out of the question, as they are not entirely suitable for this type of simulation. Our database of material models, explosive charges and projectiles is constantly growing, which will also enable us to deal with future questions quickly and efficiently.

Firing at laminated safety glass and frames

Firing at laminated safety glass and frames

We are, of course, fully aware of the fact that, even with a simulation tool as advanced as this one is, the quality of the expected simulation results can only be as good as the data input. Accordingly, the simulation still needs to be validated in order to improve the predictive quality.

Examples of some of our simulation and optimisation services during a development process are listed below:

- Construction of complex CAE models from CAD data including material properties, joining technology and separate boundary conditions

- Simulation of diverse certification requirements

- Detailed design of protective systems that function correctly and meet requirements

- Continual, iterative model optimisation and elimination of weak points

- Validation of the results on the basis of experimental data

Protect life: Our highest goal!

Explosion of a concept tank with two shrapnel hand grenades

Explosion of a concept tank with two shrapnel hand grenades

When developing protective systems, our primary target is always to protect human life while at the same time working within the given conditions to create an advanced product; in this way we not only live up to our own expectations, but also more than meet the defined requirements.

This applies, of course, to all applications in which highly dynamic processes with the potential to jeopardise the life and health of others are simulated. What would happen, for instance, if, just as two passenger trains are passing each other, a component comes of one of them and crashes into the front structure of the other? Will the structure be able to withstand this load, or do we need to undertake structural changes in order to reinforce the train driver's safety zone?

Impact of a standard projectile on the front structure of a passenger train

Impact of a standard projectile on the front structure of a passenger train

We are already dealing with questions like these, and simulating a wide variety of threatening scenarios in vehicle and special protection solutions.

THE FUTURE STARTS NOW

As we wouldn't be EDAG if we were not continually exploring new fields and possible applications, we are also working on various other matters, including the following:

- Protection of bird strike events on aircraft structures and engines using bird strike substitutes with a biofidelic approach

Conventional bird strike surrogates for corresponding tests have so far consisted either of previously killed birds, often chickens or geese, or of geometrically simplified gel-like surrogates, such as rounded cylinders. However, these simplified substitute bodies make a direct transfer to the damage caused by real birds very difficult, as these substitute bodies cannot adequately represent the characteristic force, moment or pressure curves.

Therefore, the company: crashtest-service.com GmbH has developed a new type of bird strike substitute based on real CT scan data, which addresses precisely this problem with its behavior, in that its damage behavior is comparable to its ornithological model. In order to be able to provide a corresponding simulation model for the test specimen for bird strike tests "Alpha® " during the development phase, we took on these tasks for ourselves and developed a corresponding simulation model for IMPETUS Afea.

Impact of a 1.8 kg bird on a section of an airplane fuselage structure

- Development of emergency exit systems for high-security vehicles

We can manage to keep the danger locked on the outside, but what happens if a vehicle is in an accident or has withstood an attack? Can the rescue teams still gain access? Are the passengers able to get themselves out without help? Parallel to this, we are also working on new ways of getting out of a vehicle that are a far cry from conventional emergency exit systems. - Infrastructure and property protection simulation

The applications vary from façade security for terror defense and the design of access protection concepts or terror barriers to intrusion protection in vulnerable areas and also include the simulative evaluation and simulation of specific attack scenarios. - Investigation of impact and impact scenarios on battery systems and design of specific safety components for the thermal runaway case

On account of the increasing electrification of automobiles, the question of validating energy storage elements is being discussed within the context of the verification of high-security vehicles, as the intensified use of electric power in future vehicle concepts in this segment cannot be ruled out. Accordingly, we are already looking at ways of protecting energy storage systems from external forces, so that mobility can be sustained even in an emergency.

However, if the energy storage system is damaged beyond the critical level and a thermal runaway can no longer be prevented, the corresponding components must be designed for this sudden pressure and temperature load and specific fail-safe elements, such as bursting membranes inside the battery or the cells, must be provided in order to minimize the potential danger to the occupants. We also use IMPETUS Afea for the design of these components.

We have been working with IMPETUS Afea for several years now, and various projects have added to our in-depth and detailed knowledge. Our colleagues, Eberhard Keim, Head of Department CAE & Safety and Jan Bohlen, Project Leader CAE Engineer Blast & Ballistics will be happy to help you with any questions you might have, and – always, of course, exercising the utmost discretion and confidentiality – examine them for you by means of simulation.

In our industry, safety has a very special value of its own. To ensure that we can continue to successfully protect people who, on account of their function or profession, require particular protection from attack, a new certification guideline "VPAM ERV - edition 3" came into force at the beginning of 2021. Learn more about the amendments to the certification of armoured vehicles, the latest edition of the VPAM ERV and amendments to certification in accordance with VPAM ERV as well as injury assessment with the PRIMUS Breakable® in the 30-minute recording of our Defence Online Session. Register now for the recording.