The cost and range of a BEV are decisive factors when buying a car. On the other hand, the energy storage systems in an electric vehicle should be reliable and survive accidents as unscathed as possible. Thus, cutting corners on safety is not an option. Nevertheless, the development of battery systems still has untapped potential. With the right tools and methods, this potential can be unlocked, as EDAG Engineering demonstrates using the digital twin for battery cells.

Virtual modeling and simulations are established methods in vehicle development. We use them, for example, in component development, for the optimization of safety assistants, the design of new brakes or vehicle setup. The benefits are similar in all areas of application: A wide variety of virtual tests can be carried out to evaluate and analyze systems at an early stage, to reveal and correct faults. Tests on physical models, in contrast, are much more expensive and take more time. Simulations make the development phase both cheaper and faster. Short innovation cycles have a major influence on the success of a project, especially in technology areas with high competitive pressure.

The Race for Battery Systems

The development of batteries and battery cells is just such a highly competitive field of technology. In recent years, battery technologies have made enormous progress, resulting in increased ranges, reduced charging times and more robust batteries. The technology is still young, which reflects in agile development. The need for tools and methods that support efficient and rapid development is all the more pressing.

Yet there has been a gap here so far. Until now, virtual models and simulations have hardly ever been used to develop batteries for vehicle integration. One problem is that the models first need be developed using a sufficiently large database, and then verified and validated, because a simulation model that is not valid may deliver incorrect results. So far, however, there have hardly been any suitable solutions for the development of battery systems.

EDAG Engineering has therefore taken up the issue and went looking for ways to optimize development. Subsequently, the engineering specialist developed a digital twin for battery cells. It is based on virtual models and simulations that have been verified and optimized in extensive test series. The battery specialists have focused on the areas of short-circuit simulation, thermal analyses and breathing analyses.

Short circuit simulation

There is currently no state-of-the-art simulation methodology to describe short-circuit behavior during a vehicle crash, since there is a major lack of simulation accuracy at cell level. As a result, vehicle developers play it safe and protect the battery to such an extent that it is not subjected to any stress in the event of a crash. This safety comes at the price of increased material usage and generously calculated buffer areas. The other side of the coin is a higher vehicle weight, a lower number of cells and a more complex crash design.

However, various studies show that battery cells can be very robust depending on the type of stress, and that complete protection by the battery housing is both unnecessary and leads to considerable oversizing of the battery block. Potential reach is wasted this way and resources are not used efficiently.

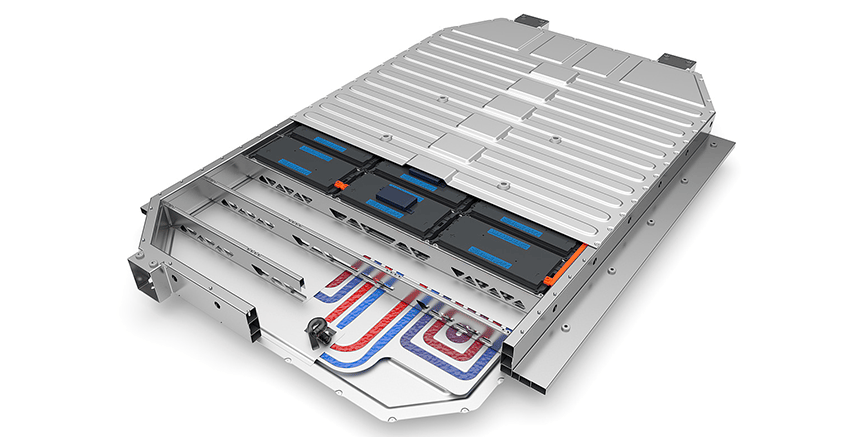

To address this problem, battery tests were carried out on standard cell formats, including destructive cell tests to develop the mechanical part of the macro-model. The result is a virtual model that can be used to investigate cell behavior at an early stage of development as part of a complete vehicle crash simulation. By adjusting the safety factor, it is possible to design the battery protection to the desired level and avoid over-dimensioning. Tests on the EDAG SCALEbat showed that using the digital twin improved the battery capacity by 52 percent and the range by 224 km.

Thermal analysis and breathing model

EDAG Engineering has also carried out extensive test series to describe the electrothermal behavior. For this, the internal resistance depending on the state of charge (SOC) was determined at different temperatures using pulse tests. The results were stored in the simulation as a characteristic diagram, together with the specific heat capacity and thermal conductivity of the cells.

These characteristic values are already sufficient for a macro-model that can be used to describe the temperature development in cells due to time-varying current flows with sufficient accuracy. This in turn provides the basis for a suitably designed cooling system for the vehicle battery. If it is oversized, resources are wasted - including valuable energy, which reduces the range. Insufficient cooling leads to high operating temperatures, especially under high loads such as acceleration or fast charging. Too high operating temperatures can reduce battery life and impair performance.

Another feature of the digital twin is the visualization of reversible cell expansions (breathing) during charging or discharging. In order to develop this method, the tests shown in Figure 9 were carried out. Stacks of pouch and prismatic cells with different numbers of stacked cells were charged and discharged at a constant C rate under the defined test conditions, and the expansion of the cell stack was measured. This allowed for the breathing feature to be implemented in the cell twin depending on the SOC.

Using this implemented functionality, it is possible to design both the tensioning of cells in the housing and the thickness of the compression pads. Especially for problems where stresses of the cell stack play a role (pressure on the module housing, natural frequencies in simulations of shaker analyses), it is vitally important to accurately predict the expansions and the interaction of the cells with the structure.

Conclusion

The full potential of the battery-electric drive can only be used by further optimizing the battery systems. The most important step is to eliminate excessive safety margins, that cause unnecessary use of material for the outer structure and over-dimensioned buffers inside, which in turn cause high costs and a lower number of cells. When competing for customers, however, range and the price of the vehicle are important factors.

Modeling and simulation or the use of digital twins is therefore essential in the development of efficient electric vehicles the battery systems of which effectively use the available space and deliver higher ranges for the same volume. The use of these simulation methods allows for a more progressive design of the energy storage systems while keeping costs low and without compromising the high level of safety.

If you have any questions on the EDAG Group's cell twin for short-circuit and electro-thermomechanical simulation, please contact Stanislaw Kefer, Project Manager Vehicle Safety and Battery Simulation, or Nishant Jakhiya, Advanced Simulation Engineer at EDAG Engineering. Find out more about the development of the methods and tools and the potential of the digital twin in the white paper "Digital Cell Twins: Using virtual models to make battery development more efficient", which you can download here.