We're travelling along the motorway to the accompaniment of our favourite song. The voice assistant warns of traffic congestion ahead – and then the telephone rings, and we use the hands-free system to take the call. Everyday scenes that make one thing clear: in-car audio systems are becoming increasingly important. Radio, telephone and media playback long ago found their way into all vehicle classes – on top of these, there are concierge services, acoustic vehicle alerting systems (AVAS), emergency call systems (eCall), in-car communication, to name but a few. Their complexity is constantly increasing, and with it their energy consumption.

Top quality sound packages are what the customer wants: more and more money is being spent on a growing number of loudspeakers, amplifier channels and other items. On the other hand, on account of legal requirements and advancing developments, vehicle manufacturers are transferring more and more functions to audio systems - after all, this modern equipment increases the attractiveness of the vehicle and offers interesting sales margins.

And what about energy consumption?

At the initial stage, nobody thinks of energy consumption. Yet this is an important factor, as, through the million-fold scaling in the vehicle fleet, even slight amendments to electric loads (as with audio systems) can have an enormous effect on overall consumption. To put it in simple terms: if even minimum amounts of energy are saved in the car, these might at first glance seem insignificant – but if all the cars on the road are included in the calculation, CO2 emissions can be significantly reduced.

But how can the electrical energy consumption of in-car systems be measured in a way that is repeatable, comparable and conclusive? Nowadays, details of the pure amplifier values are generally given in watts – without any measuring or boundary conditions. However, this alone is not enough to generate really meaningful values for the development work carried out by engineers and technicians. The Automotive Audio Energy Efficiency Test Cycle (AAEETC), which is based on a usage model, provides a solution to this. This test cycle reflects the power used by various sources (entertainment, telephone, warning sounds etc.) with clearly defined basic conditions and the usage behaviour of an average power user.

Electric cars are gaining ground

There is a further development which makes looking at the electrical energy consumption of audio systems more interesting: electric cars. The introduction of a wide variety of partially or all-electric drivetrains in the form of 48V mild hybrids, serial and parallel plug-in hybrids (PHEVs), battery electric vehicles (BEV) and fuel cell/hydrogen (FCEV) powertrains will bring about the radical transformation of the automotive market in the foreseeable future.

Driven by subsidies and a general environmental awareness which is more and more influencing consumers in their buying decisions, the worldwide market share of electric cars is on the increase. The development of sustainable products is thus becoming more and more important, and using a standardised process to measure the power consumption of audio systems is one of the many enablers here. Product development engineers will be able to make better decisions, and therefore make a positive contribution in terms of sustainability.

Every additional watt has an adverse impact on range

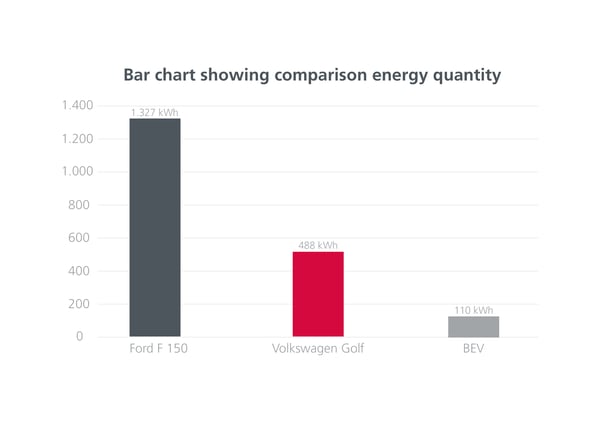

Why every watt counts with electric cars can be seen in a comparison with combustion engines: engine fuels can be stored relatively easily in containers. Converted into electrical dimensions, an eighth generation Volkswagen Golf (2021 model) with its standard 50-litre tank can carry 488 kWh's worth of energy around with it (1 litre of petrol = 9.76 kWh). An optional version of the 2021 model of the best-selling vehicle in North America, the Ford F150, can carry up to 136 litres. This is equivalent to an impressive 1,327 kWh.

Electric cars are a very different matter: the largest batteries currently installed have a capacity of approx. 110 kWh. Although they make an outstanding impression on account of the greater efficiency of their powertrains, and battery capacities will rapidly increase in the near future, the total volume of usable energy is still substantially below that of vehicles with combustion engines. When developing E/E (electrical and electronic) components, therefore, vehicle manufacturers must pay close attention to the consumption of the electrical components and their efficiency: every additional watt has an adverse impact on range and a direct influence on the sustainability of the vehicle throughout its entire life cycle.

Saving the annual CO2 emissions of a small town

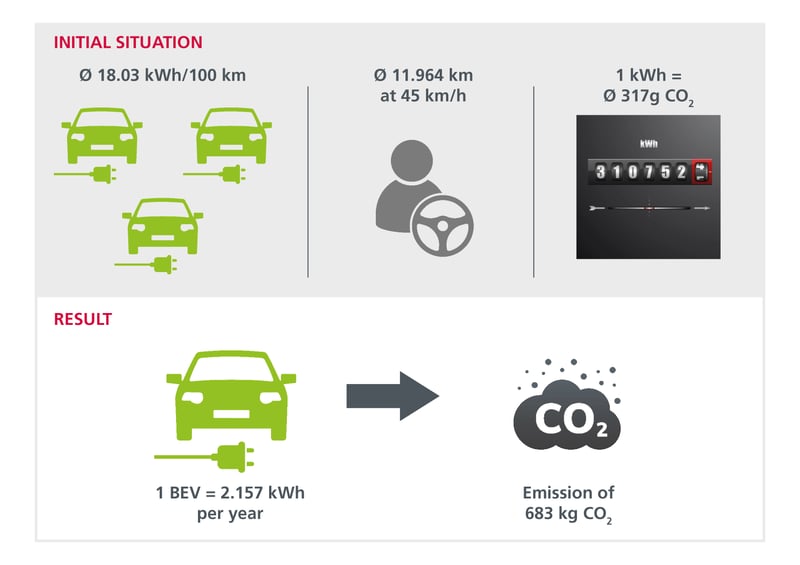

But how does an audio system affect the energy consumption of a battery electric drive system? It is worth having a look at a few figures here.- 18.03 kWh/100 km: this is the average consumption of the top ten electric vehicles sold in Europe (charging loss not included)1.

- 11,964 kilometres2 is the distance the average European drives in his/her car, travelling at a speed of 45 km/h3.

- The generation of one kilowatt-hour of energy in the EU results in the emission of an average of 317 g of CO2.

This means that the operation of an electric car calls for 2,157 kWh a year (charging loss not included) – leading to emissions of 683 kg CO2 a year. In 2020, a total of 1.4 million electric vehicles were sold in Europe4. If the electric and electronic design of these vehicles were to be altered in such a way that the continuous power was reduced by just 1 watt (-0.01235 %), this would result in a total saving of 118,090 tonnes of CO2 per year of operation. To elucidate: this is equivalent to the total annual emissions produced by 173 electric vehicles! A further advantage is that, compared to the task of improving powertrain efficiency or the aerodynamics, small modifications can be made to the E/E components more quickly and then integrated into existing series.

Suggestion for the Automotive Audio Energy Efficiency Test Cycle (AAEETC)

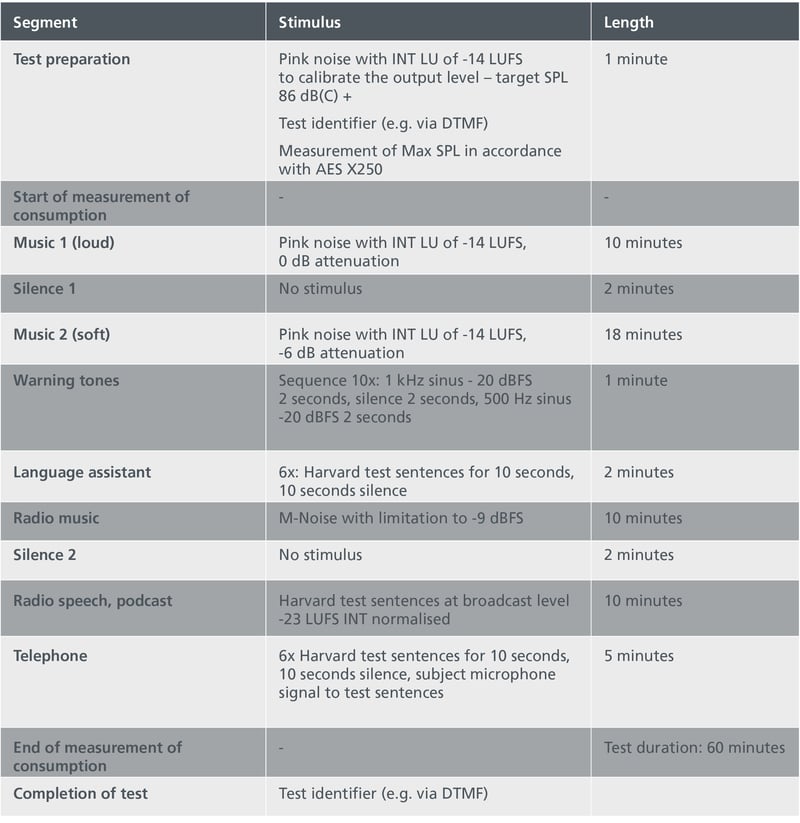

And now back to the test suggested as a possible basis for improvements. Audio systems in in vehicles are put to different use by different people: some listen to loud music, others use the radio a lot, telephone a great deal, or perhaps use no audio sources at all when they are driving. When it came to a standardised usage test, the challenge was to take all these variables and find a mean value. A similar challenge was also posed by the development and incorporation of the standardised test procedures prescribed by law for the measurement of consumption values (NEDC, WLTP and GB T CLTC). Although the individual is not well represented by the model here, the test results allow for comparability between the competitors within a class, and meaningfulness and reproducibility between the different test bodies. These conditions can be transferred to the AAEETC. It is therefore possible that the test cycle might, in the future, be further improved through anonymously determined usage data of OEMs and providers of mobility services.

Test description of the AAEETC

Basic conditions:- System must be booted and ready for use

- If specific filters are applied for some sources ("tunings" or EQ sets) these must be activated in the test case concerned

- Supply voltage 14.4 V

- Current measuring device with logging function, logging active during the measuring cycle

- Temperature: 20°C

- Test duration: 60 minutes

This example shows that sustainability can mean genuine added value for everyone, and also bring about a competitive edge. The Automotive Audio Energy Efficiency Test Cycle (AAEETC) is a tool for developers and a suggestion of how the energy consumption of audio systems might be reproducibly and reliably measured and evaluated. Building on this, improvements can then be carried out. In addition, the measurement results might also create greater transparency for the consumer: fairer comparisons between competitors become conceivable.

If you are interested in these technologies or other fields of application, our Audio System Engineer Thomas Baumgartner will be happy to help you. For more information, download the white paper "How much CO2 does my car radio emit?".