The German truck and bus manufacturer has drawn up detailed life cycle assessments of its vehicles and published the results in the form of environmental product declarations. Project partner EDAG took care of the data collection and analysis and of carrying out the life cycle assessment (LCA). The resulting environmental product declarations (EPD) can also provide the manufacturer with valuable advice for optimizing both the vehicles and the manufacturing processes and strategies.

The question of how climate-friendly or damaging the different means of transport are is currently the subject of intense debate. The Federal Environment Agency's contribution to the ecological assessment of types of transport [https://www.umweltbundesamt.de/sites/default/files/medien/479/publikationen/texte_156-2020_oekologische_bewertung_von_verkehrsarten_0.pdf] can only provide a rough outline. It compares trains and long-distance buses, for example - with no mention of the different powertrain technologies used in buses.

Businesses and local authorities wanting to buy their buses and coaches not only on the basis of purely economical but also ecological criteria therefore need more detailed information. Some cities and municipalities have already made a voluntary commitment to invest in climate-friendly projects. It is conceivable that legal requirements might also place higher value on emissions in the future.

EPDs for four buses

MAN Truck & Bus SE supports the orientation towards reliable information regarding the individual vehicles, and is leading the way by drawing up environmental product declarations (EPDs). The high acceptance enjoyed by EPDs is based on two factors: standardized preparation and certification of the results by an independent body.

On the one hand, EPD standardization is defined in the ISO 14025 standard, while on the other there are already separate product category rules (PCR) for many product groups, providing a product-specific framework for the generation of a life cycle assessment (LCA). In the case of buses, this is PCR 2016:04 Public and private passenger buses and coaches (2.0.1) (valid until December 4, 2024).

In a public tender procedure, EDAG was awarded the contract for several EPDs for buses by MAN, and has now assisted with the creation of a total of four EPDs. The LCA created by EDAG and the values measured were checked and verified by the IVL Swedish Environmental Research Institute in its role as an independent auditor.

Extensive data acquisition

Data acquisition is an important part of the task. Several sites are involved in the production of the buses. Coordination of the data collection and its subsequent processing took up a large amount of the time required. Although the existing environmental management systems to some extent made it easier to collect the data, some of the data supplied was in different formats and so had to be homogenized first.

In some points, it was not always possible to access complete datasets for the life cycle assessment. One example of this was the tires: 95 percent of the material used was directly quantifiable – the remaining five percent came under the manufacturer's trade secrets and could therefore only be approximated.

Own models required

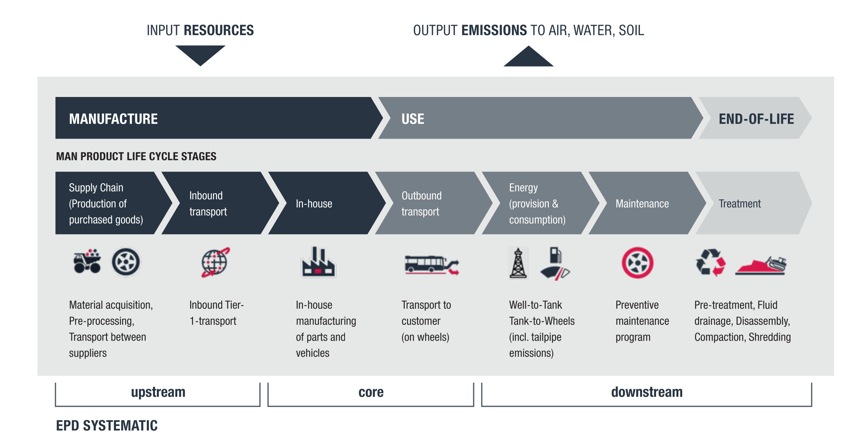

The final document, the environmental product declaration (EPD), is based on the calculations of the full life cycle assessment (LCA). This takes the entire life cycle into account, from the extraction and processing of raw materials to product service life and disposal. The modeling of the life cycles of the buses and the calculation of the life cycle assessment indicators was carried out using Sphera's "LCA for Experts" software (previously known as "GaBi") [https://sphera.com/product-sustainability-software/].

The entire life cycle is assessed (Source: MAN Truck & Bus SE)

The entire life cycle is assessed (Source: MAN Truck & Bus SE)

To this end, EDAG's LCA experts designed their own models, taking the framework conditions defined in the product category rules into account.

This model can be used not only to calculate the climate-related and environmentally relevant factors of a bus, but also to identify "hot spots", those critical points that will have a particularly negative impact on the environmental assessment. With this instrument, MAN can find out which parts have an especially large carbon footprint. The data can then be used to derive goals and measures to make the products more sustainable.

Looking to the future, car manufacturers will also be required to draw up certified life cycle assessments. Corresponding product category rules for EPDs in the passenger car sector are to be published before the end of this year.

Where this development might lead is already clear today. Last year, EDAG created product carbon footprints (PCF) for Tier 1 supplier preliminary products, which the OEM, our customer, had requested. In this way, the OEM can calculate carbon footprints/emissions and then use these as a basis for reporting and for monitoring reduction targets.

Experienced external support

In its role as a partner, EDAG can offer valuable, multi-level support with the environmental assessment of products. The team of experienced LCA modelers draws up full environmental assessments that determine the diverse impacts on mankind and the environment and go far beyond a survey of global warming potential. The team is familiar with data acquisition and analysis, and with the use of the software tools and databases required, taking the relevant standards and regulations into account.

An environmental management system in accordance with ISO 14001 can contribute to a good database. The all-round engineering service provider can also provide the support of experienced experts to implement the relevant processes and systems – at both the manufacturer's and its suppliers' premises.

In addition, the EDAG specialists can combine their sustainability skills with technical knowledge of the mobility industry and thus offer further advice on the adaptation and optimization of the vehicle as soon as a life cycle assessment has been carried out, without having to fall back on the the services of third parties.

Finally, EDAG also has on board industrial specialists who can provide helpful assistance in the fields of manufacturing and production processes. This means that, from a single source, progress can be made in environmental goals, decarbonization, increasing efficiency and reducing costs.

Should you have any questions about environmental assessments and life cycle assessments, contact Alexander Erler, development engineer at EDAG Engineering. Further information on the generation and use of environmental product declarations (EPD) can be found in the white paper "EPD: Standardized Environmental Assessments for Buses", which can be downloaded here.