Hydrogen is being used more and more as an alternative to the battery-electric drive. To date, the initial filling has posed an enormous problem. Until the level of purity required for fuel cell operation is reached, a great deal of hydrogen gas is wasted. However, there is now an industrial procedure which saves both material and time: refueling in a vacuum chamber.

Although the battery electric vehicle (BEV) is regarded as being particularly efficient, it is not always able to meet the challenges that present themselves. Especially when high performance or long-term operation are required, alternatives not requiring lengthy charging must be found.

One possibility is hydrogen-based powertrains, either with fuel cells (H2 FCE) or a combustion engine (H2 ICE). Both versions require a pressure vessel to serve as a tank for gaseous hydrogen, which generally has a fueling pressure of 350 to 700 bar. For safety reasons, there must be no oxygen in the tanks, as otherwise there is a risk of explosion. This can be avoided by first completely flooding the tank with nitrogen.

There is, however a difference between FCE and ICA operation: the nitrogen, too, is harmful to the fuel cell. The maximum tolerable nitrogen content is 100 ppm. This means a hydrogen content of ~99.99 percent.

Existing Procedure

Existing Procedure

The initial filling of the pressure vessel or the entire tank system is based on the principle of dilution. To begin with, there is atmospheric air in the system, with its main components of approximately 78 percent nitrogen and just under 21 percent oxygen. To avoid any risk of explosion, the vessel is flushed with nitrogen to lower the oxygen content to below four percent.

Hydrogen is now forced into the tank, and the pressure reduced to release the mixture it contains. On account of the different densities of the two gases, however, more hydrogen than nitrogen escapes, further complicating the process. This process of alternating pressure flushing must be repeated until the nitrogen content has been diluted to below the desired 100 ppm mark.

This process generally takes six to eight hours, and involves a great deal of manual input. To this is added a high gas consumption, as the hydrogen that escapes is contaminated with nitrogen and so cannot be put to any further use.

Fueling in the vacuum chamber

Development engineers from EDAG have now industrialized the process, with a method for initial refueling that both conserves material and is faster. Their concept is based on the use of vacuum technology. One problem is that although the typical type 4 pressure vessel can withstand high internal pressure, it is not suitable for an internal vacuum attended by high external pressure. The outer cover, which is made of carbon fiber reinforced polymer (CFRP), would in fact be able to withstand this pressure. However, the gas-tightness of the tank is guaranteed by a liner inside the CFRP shell, and this plastic vessel would collapse under the external pressure.

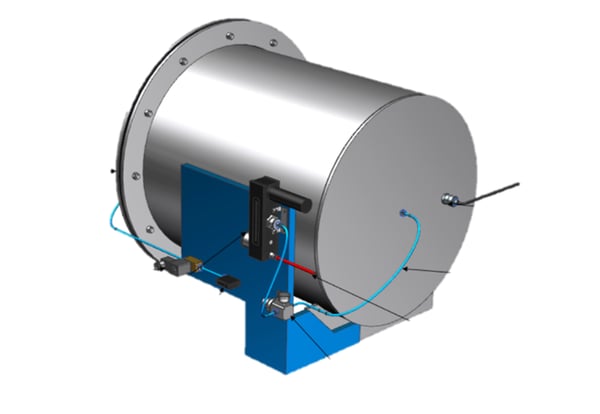

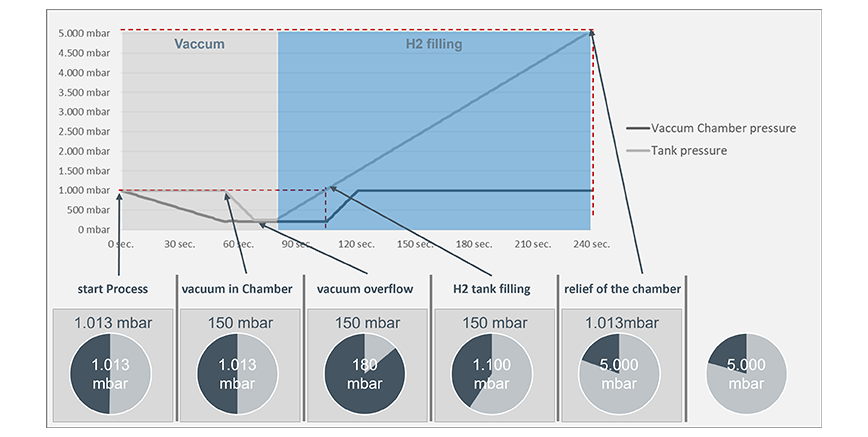

EDAG's experts therefore came up with the idea of relocating the entire system to a closed chamber. With the tank closed, a vacuum is first created in the chamber. This creates an overpressure – relative to the environment – in the tank. If the tank is now opened, the air it contains flows out. After this has also been removed from the chamber, there is a vacuum both inside and outside the tank – but no pressure drop, so the liner is not affected. The hydrogen can now be fed in.

Quantifiable advantages

In a project outline, a system suitable for filling Type 4 pressure vessels was initially designed by EDAG with the support of the plant construction team in Recklinghausen. Cooperation partner NPROXX provided the tested tank and joined in discussions of technical issues. The pilot vacuum chamber was then set up at EDAG's H2 competence site in Bremen, where the process was successfully tested. The result is containers filled with 100 percent H2, so the hydrogen can be used in a fuel cell without any problems.

In contrast to the traditional process, no gas is wasted in this way. With this method, the amount of hydrogen used prior to the actual filling is reduced by 100 percent, and the process time is reduced by a factor of 10. The manual input involved in filling can be completely eliminated by a fully automated process. Taking the process as a whole, approximately 30 percent of the manual work is saved. What is more, gas inertization using nitrogen becomes completely superfluous.

One further advantage is that the results of trial operation indicated a 70 percent reduction in the system's operating time. This in turn involves lower maintenance costs, less wear and tear on the system, and a significantly reduced energy consumption throughout the entire process.

Practical application in the pipeline

EDAG customers can now make use of this patented process and get involved in the industrialization of H2 fueling themselves. The industrial service provider offers the options of using it at one of its own locations, or operating a suitable system at the customer's site. If you have any questions, please contact Marius Koch, manager of our Bremen branch.

EDAG also offers a webinar to provide interested parties with further information on how the vacuum chamber works and present data that has been acquired. Register here.