With the networked, autonomous CityBot, not only has EDAG developed a self-driving vehicle for various different tasks in urban areas, but at the same time, has literally also put the design of the entire chassis on a new footing. The newly developed cornering modules are worthy of particular note. And in addition, a new type of rear axle has been installed in the people mover. The space-saving, cost-cutting concept is also suitable for passenger cars, motor homes and commercial vehicles.

A driverless robot car capable of transporting people and goods, of emptying bins, mowing lawns and even sweeping the road - that is the EDAG CityBot. This in-house development of a networked autonomous vehicle can be adapted to particular tasks by using different modules, and it must therefore meet many different requirements.

The unladen weight of the robot car's traction module is around 750 kg, while that of the functional backpack modules starts at 100 kg. If these are intended for transport or disposal tasks, then a payload of at least 130 kg is possible. The unladen weights of the trailer modules with an additional axle range from approx. 500 kg to 975 kg for the people mover variant, so the total weight increases to more than 2 tonnes.

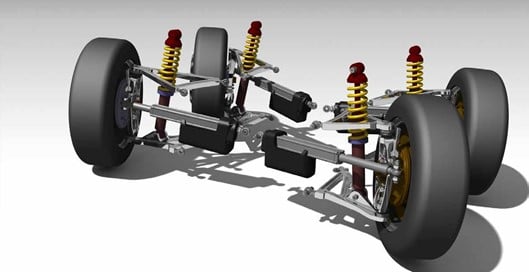

Tight curve radii, turning on the spot, diagonal and transverse driving and a maximum speed of up to 60 km/h present new challenges in chassis development. Especially where passenger transport is concerned, just as much care must be taken to ensure high comfort and driving safety as high maneuverability and robust design. Other targets for development included a scalable design and increased efficiency in the manufacture of the chassis and vehicle construction.

Innovative overall concept

In the CityBot, EDAG has combined numerous in-house developments, to create an intelligent vehicle. Know-how from many fields has been incorporated: chassis and powertrain, object recognition, self-localization, trajectory planning and vehicle control unit (VCU). The engineers were able, for example, to draw on experience gained from the autonomous truck for transporting harvested crops, but in-house expertise also came into play in the development of a two-lane simulation model capable of representing the large steering angles and innovative driving functions.

For the chassis, which is designed for excellent maneuverability, different axle loads and its adaptability to a wide range of applications, the EDAG specialists decided to completely redevelop the front and rear axles, in a form the like of which has never been heard of before. The only common feature is the use of coilover struts mounted on symmetrically designed double wishbone axles and a new wheel carrier concept for the individual wheel steering system.

Low-cost, comfortable axles

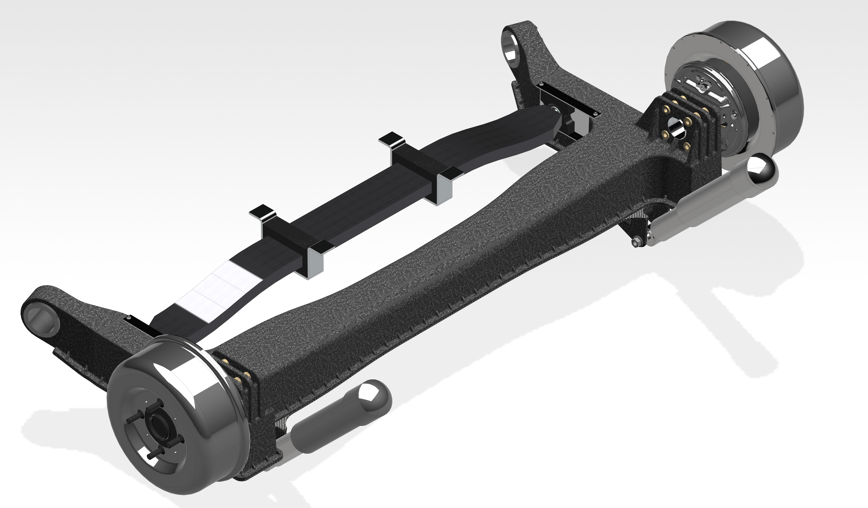

Whereas the CityBot is based on four corner modules at the front, semi-independent suspension with a transverse leaf spring is used in the people mover. With this axle concept, it is possible to specifically improve both driving comfort and safety while keeping complexity, costs and the required installation space to a minimum.

The transverse installation means that only one spring is required, and no additional stabilizer bar is needed. Longitudinal suspension travel is increased, and S-sway when driving over transverse joints, as occurs with rigid axles with longitudinal leaf springs, is completely eliminated. This significantly improves driving comfort with both one-sided and two-sided deflection. Compared to twist-beam rear suspension, the semi-independent suspension with the cross member mounted close to the wheel center has one key advantage: especially where commercial vehicles with high axle loads are concerned, it ensures that adequate transverse support is provided even under high lateral forces. Additional transverse support is provided by the transverse leaf spring, which is connected to the trailing arms by means of asymmetrical elastomer bearings. It is also supported by the chassis. This double parallelogram ensures that the axle retains its tracking stability under the influence of lateral forces, and does not push the wheel into toe-out.

Other advantages include a weight saving of around ten percent and the possibility of scaling the axle concept to suit different vehicle categories, axle loads and track widths. At the present time, the axle is designed for a maximum axle load of two tons. It is therefore especially suitable for use in lightweight commercial vehicles with a gross vehicle weight of up to 3.5 tonnes, as a rear axle for motor homes and caravans, and also for use in high-roof station wagons and local transport vehicles.

The space-saving design is particularly advantageous where passenger transport is concerned. As the transverse leaf spring is fully integrated into the axle, the overall height remains very low. Minibuses, motor homes or the CityBot's people mover benefit from keeping the floor height for the interior low, as this ensures easy entry and a low center of gravity.

Interesting extension options

The innovative semi-independent suspension with a transverse leaf spring already reduces weight by around 10 percent; with a fibre composite axle beam, a further weight saving of 6 to 8 kg can be achieved.

Even the traditional variant of the metal semi-independent suspension is composed of very few components. Accordingly, no additional costs are expected compared to conventional rigid axles. The maintenance requirements are also comparable.

In the course of a concept study however, the possibility of manufacturing from fiber composites was also looked into. According to this study, a semi-independent suspension axle in CFRP (carbon fiber-reinforced plastic) design would be even easier to manufacture, as the axle beam consists basically of just two parts - the upper and lower shell - which need to be bonded together. With the same load-bearing capacity, weight savings of 6 to 8 kg can be expected in the fiber composite variant.

A further development option presents itself in the area of flexible adjustment to the axle load. An adjustable spring stroke ratio could enable the height level and wheel spring rate to be kept the same, regardless of the load. This eliminates the need for complex, high-maintenance pneumatic spring systems in its design, which in turn cuts costs.

Space-saving electrification

Building on these chassis designs, the CityBot has an electric powertrain which also has a number of distinctive features. Wheel hub motors produced by the Slovenian manufacturer Elaphe are used; these provide the required torque and are already equipped with 7-inch drum brakes in case motion retardation by means of regenerative braking should be insufficient.

The individually articulated wheels have a maximum steering angle of 135°. In addition to driving straight-ahead and cornering, this all-wheel steering system can handle three special driving functions: diagonal driving at 10 km/h with a steering angle of ±45°, 360° turning on the spot, and diagonal driving (steering angle ±90°) at up to 6 km/h, for parking for example. The agile robotic vehicle is capable therefore of traveling not only on ordinary roads, but also on narrow park paths, to trim hedges for example.

"Inner values" are what count

The EDAG CityBot shows that while eye-catching car bodies and powerful engines act as attention magnets for consumers at car shows and mobility events, the "underbody" is far more interesting to vehicle production experts. The powertrain and chassis form the driving chassis, and so determine vehicle dynamics, driving comfort and safety. Felix Mergner, Leader Virtual Function Development at the EDAG Group, will answer any questions you might have on these subjects. Further details of the CityBot's intelligent chassis can be found in our white paper "With smart powertrain and chassis technology through the city with a future", which can be downloaded here.