The development of medical devices is a complex and multi-layered challenge that encompasses several disciplines and aspects. In order to meet the high demands, integrated product development is required that combines technological innovation with the highest quality and safety. The main challenges that arise during the development of a medical device are examined in more detail below.

Suppliers of medical devices face many different challenges. These include the long approval times and the associated high costs for clinical trials. The real test trials required for this also cause difficulties. The challenge here is to find answers to ethical questions, such as avoiding animal testing and using scarce blood resources responsibly, while still achieving meaningful results. Synthetic alternatives to blood generally do not have the same properties in terms of density, viscosity and composition. In this case, meaningful simulation models can help - if you have the necessary tools and expertise in-house.

Another task is to coordinate communication via agile project management between design, simulation, tolerance and quality management as well as prototyping and testing. If these are not carried out from a single source, delays can quickly occur. However, long development cycles are countered by high competitive pressure, as a large number of suppliers are entering the market. With streamlined development processes and proven methods, new technologies can be implemented at an early stage and the time to market can be shortened.

At the same time, the development of new technologies is subject to high cost pressure. Small and medium-sized companies in particular are often faced with the challenge that investments in simulation models and calculation software can put a strain on the cost structure as they are not fully utilized.

In order to reduce the high development costs and still create efficient solutions, many companies rely on external partners. They can take on tasks such as tolerance calculations and CAE simulations that cannot be mapped internally, or provide support in the development of prototypes and the optimization of production technologies.

Various specialist disciplines in demand

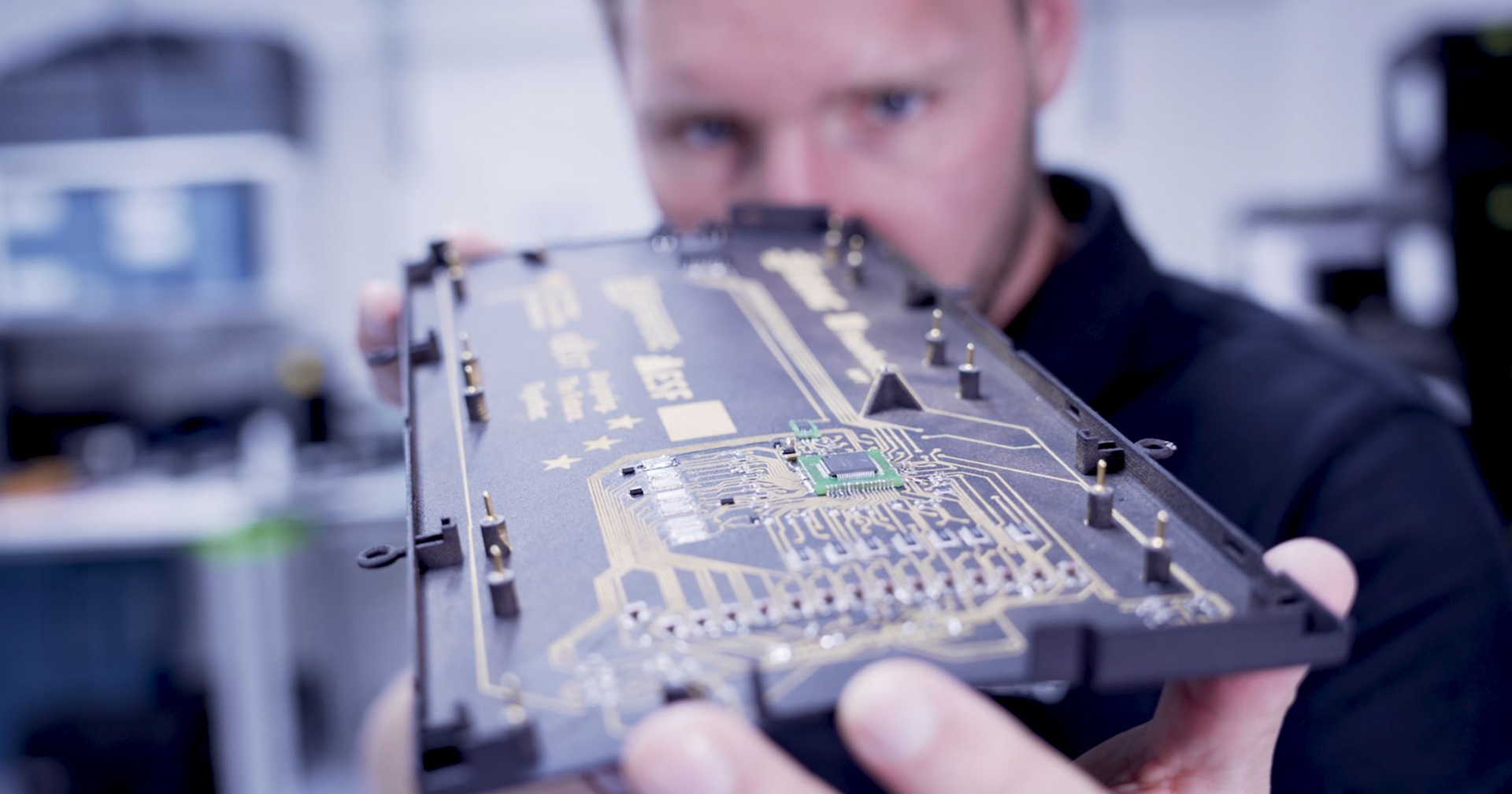

A key feature of medical device development is the need for collaboration between different specialist disciplines. One example of this is the development of a dialysis machine that integrates complex systems for blood flow monitoring, temperature control and automatic alarm systems.

Close cooperation between experts from the fields of medical technology, plant engineering, electronics, software development, design and materials science is essential in order to develop innovative, cost-effective and easy-to-use products.

For example, the user-friendliness of medical devices not only has an impact on the application process, but also on the cost of treatment. Complicated handling can increase treatment times and thus reduce productivity in clinics and practices. One example of successful user-friendliness is the use of integration groups in dialysis machines, which simplify the connection of tubes and lines and thus shorten the preparation time for treatment. This also benefits patients, who do not have to spend as long in surgeries or hospitals.

Complexity and innovation

State-of-the-art and digital technologies play a central role in the development of innovative medical devices, for example:

- Simulative design and validation tools,

- Rapid prototyping,

- Digital Mock-Up (DMU) and

- the connection to automation technology (OT).

These tools make it possible to check the functionality and manufacturability of products during the development phase and identify optimization potential. In this way, the use of materials, strength, tolerances and thermomechanical and fluidic properties of products can be optimized.

Integrating these technologies into early development phases can shorten development times and speed up time to market, which is crucial in the face of intense competitive pressure. In addition, digital prototypes and CAE/CFD simulations can be used to identify and eliminate potential weaknesses before physical prototypes are produced.

Steps to the finished product

Tolerance management is a key element in the development of medical devices. The functionality of a product depends to a large extent on compliance with the tightest tolerances, especially when it comes to safety-critical applications such as in medical technology. Deviations from the specified tolerances can impair functionality and lead to serious problems. CAE simulations help to analyze these tolerances and optimize production.

A further step is digital function development. This involves identifying and eliminating potential problems in practical use. In a dialysis unit, for example, it must be ensured that the blood is not heated too much at certain points, that the flow does not lead to harmful hydrodynamic shear stresses and that added agents and medication are well distributed. The underlying effects are determined using CFD (computational fluid dynamics). Based on the results obtained, the geometry can then be adapted to guarantee safe functioning.

The development process is validated using rapid prototyping as well as traditional prototype construction. This results in solutions that are specially tailored to customer requirements.

Conclusion

The development of medical devices is characterized by numerous challenges that require close cooperation between different disciplines and a holistic approach. At the same time, there is great competitive and cost pressure. If you want to hold your own in this market, which demands constant innovation and high quality, but also short development times and low costs, you should look for partners who can bridge staff shortages or take on certain tasks.

However, care should be taken to ensure that interdisciplinary work and an eye for the "big picture" are standard. A mindset that includes sustainability, careful use of resources and waste avoidance is also a widespread requirement in the medical device industry. EDAG can score points here in all areas - with a team that includes experts from various disciplines, with extensive experience in the development of calculation and simulation models and, last but not least, with its own tools for optimizing the climate friendliness of products.

Do you also need support in the development of medical devices? EDAG promotes strong partnerships in order to achieve results efficiently and quickly in close cooperation and to achieve maximum impact together. Markus Reisinger, Head of Department at EDAG Engineering, tells you what this can look like in practice. You can also download our white paper "Integrated product development in medical technology" right here, which uses the development of a dialysis device to show you how the various development disciplines work together to create an optimum solution in a short time and in efficient processes.