The use of AI technologies is a growing trend. Everyone is talking about algorithms, heuristics, statistical models, big data and machine learning. Artificial intelligence and big data are often mentioned in the same breath. AI helps to prepare and analyse large volumes of big data.

AI enables machines to perform cognitive functions similar to those of humans, to learn from them, and then take expedient action. In this way, data can be analysed and evaluated, and this in turn forms the basis for solving problems. But AI can do so much more. The self-learning system is developing all the time, and adapts its behaviour to what it has learnt, to achieve continuous improvement.

Big Data on the other hand is a term that describes large volumes of data that need to be analysed so as to provide good results.

AI und big data – the perfect match.

AI can be used, for example, for process optimisation or in the development of new components (e.g. in combination with simulations). In the automotive industry, autonomous cars such as the EDAG CityBot would be almost impossible without it. AI is currently changing the the world as we know it.

One thing is very important: AI loves large amounts of data, and the larger the data, the better AI can analyse and learn. Data quality plays an important role in this partnership. Incomplete or erroneous data must first be corrected manually before it can be used in AI projects.

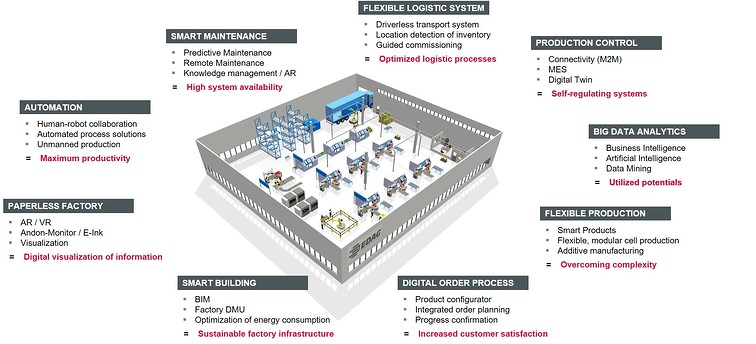

The Production IT team at EDAG Production Solutions already has many years’ experience in these technologies, and can look back on a wide range of successful projects. Our smart factory solutions can improve all manufacturing domains. Yours, too.

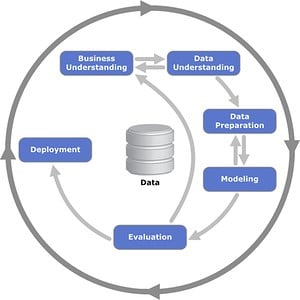

Generally speaking, the projects run through three phases:

- Operationalisation

- Modelling

- Implementation

Good data – bad data. Time and effort make the difference.

We have noticed that there is a constantly recurring theme in our projects: the quality of the data. On average, 60% of the implementation time in AI projects is taken up with the manual cleansing of noisy, incomplete or incorrect data.

We have noticed that there is a constantly recurring theme in our projects: the quality of the data. On average, 60% of the implementation time in AI projects is taken up with the manual cleansing of noisy, incomplete or incorrect data.

This has one major disadvantage: The often painstakingly devised solution is not freely scalable, but must be adapted for each domain, and this involves considerable expense. This means that the fun factor can quickly give way to a certain disillusionment for customers. Poor data quality also increases the number of loops in CRISP-DM (Cross Industry Standard for Data Mining) in individual projects, which also adds to the cost.

Quality is what counts!

Any companies that are interested in or already thinking about the use of AI technologies should therefore always ask themselves the honest question: “How good is our data?” Generally speaking, an AI system is only as good as the data on which it is based. It is difficult, for example, to optimise inventory levels if 30 percent of all master data is redundant or otherwise incorrect.

EDAG Production Solutions presented this subject and the company’s product portfolio at the 15th Digital Factory Congress. Our smart factory solutions can improve all manufacturing domains. This calls for good data, so that our customers can enjoy not only the project, but also the subsequent results.