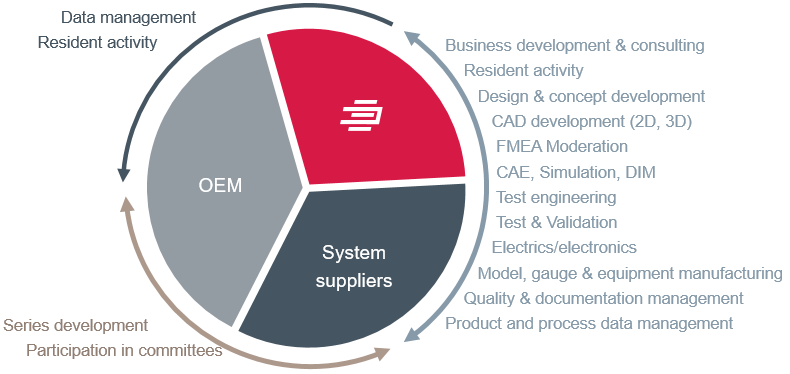

The combination of shorter product cycles and constantly increasing vehicle complexity is making ever-increasing demands on OEMs and their suppliers. In product development processes in particular, a great deal of the responsibility lies with the system suppliers. The system supplier is often the interface between the OEM and Tier 2 or Tier 3 suppliers and/or engineering service providers.

Successful collaboration between system supplier, OEM and engineering partner requires not only the necessary technical competence and qualifications, but also cooperation that is based on partnership, transparency, trust and clear expectations during each project phase. Even during the procurement process, you can have a vital impact on the choice of the ideal supplier, and, consequently, your chance of being awarded a contract by an OEM, by defining what you require of a product or service to your Tier 2 or Tier 3 supplier or engineering partner in a clear and structured way.

However, the compilation of bid documents is very complex: Even the smallest error in the documents can result in disqualification and the loss of a potential contract.

The right structure makes many things easier. Your job, too.

Most suppliers often regard submitting a quotation or tendering a bid as stressful, regardless of whether they are an existing supplier or a new supplier. In addition to their day-to-day business, working under time pressure, and taking into account whatever formalities have been prescribed, they have to prepare and draw up complex and complicated bid documents. Various departments or sections have to often work together during this process, making time management even more critical and adding to the complexity. So it can quickly happen that, when looking through the quotations your engineering service providers have submitted, you realise that the documents fail to meet your requirements, have not been prepared professionally enough, or that important information is missing, giving rise to the impression that this supplier does not have the required qualifications. And so a potentially good supplier falls by the wayside. The better your brief, the more precisely the supplier can tailor his offer to your requirements.

Structured bid documents are therefore the basis for comprehensible, valid and technically sound quotations, and guarantee successful collaboration from the very start. As an engineering service provider, we at EDAG assist our customers with the preparation of bid documents every day and we know exactly what needs to be done to make life earier for service providers at this early stage, and what structure a service provider brief should have.

Key requirements for quotation process:- Research for the pre-selection of suitable suppliers

- Definition of possible substructures/possibility of integrating Tier 2 or Tier 3

- Nomination of stakeholders for the project as contact for inquiries

- Identification of specific risks (need for special qualifications or similar)

- Style sheet for quotation

- Identification of further process formalities

Specify the required scope of work as precisely as possible, such as production of a specific component with the exact specification of materials. Provide any initial drawings or design drafts.

Additional relevant information may include:

- A time/milestone schedule, also for approval processes, testing, etc.

- Further information that may be of particular relevance during the quotation phase, e.g. quantities, call-off batches of components, information on locations in close proximity to the OEM.

- Personnel set up: Has the project leader been designated? Is there a permanent team that is available for meetings with the OEM?

- Technology/certifications: What technical requirements must the service provider be able to meet (Plattforms, software programs, etc.)? What forms of certification are absolutely essential for awarding the contract?

- Must additional requirements also be met? (e.g. sustainability)

Thomas Ketterle, Key Account, is fully conversant with all of the processes, guidelines and requirements that really matter in the bidding phase, and can help you to draw up the perfect service provider brief that can eventually become a successful project. They also has valuable tips that will make things easier for you during the bidding phase , despite the incredibly tight time schedules.

Would you like detailed guidelines on how to quickly create the optimal service provider brief in order to find the best partner for an OEM project? Listening carefully and asking the right questions beforehand will ensure that you find out everything your service provider needs to know. Download the white paper now to find out more about our countless successful "speed dating" sessions with OEMs and about what you need to know and take note of.