Circular economy, predictive maintenance, adaptable production plants – industrial production still offers huge potential for greater sustainability. But a wide range of data is essential if advantage is to be taken of the opportunities,. Some of this is already available – what we need to do now is to make it usable with suitable concepts.

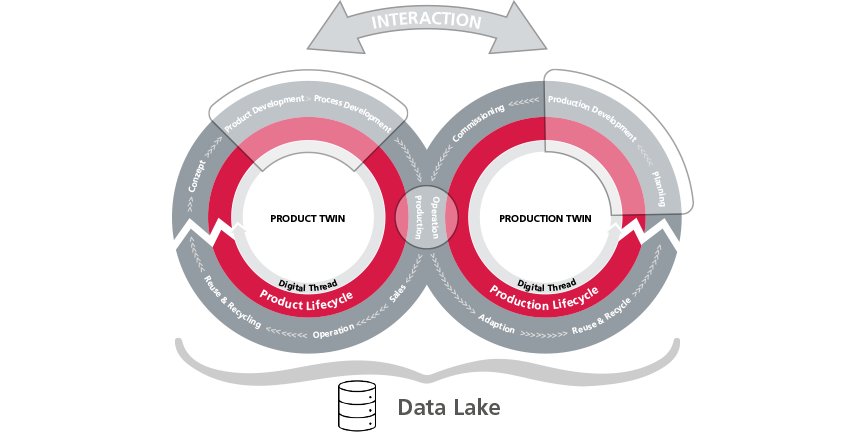

Asset Administration Shell and digital nameplate, digital twin and industrial internet of things – digital transformation is flooding the industry with information. Initial data on components, machinery and systems, vital data from the ongoing production process, historical data that can be used to identify developments and anomalies – plus new technologies for everything from data analysis to machine learning (ML) and other forms of artificial intelligence (AI) – together, these provide a broad basis for more automation and autonomous processes within the context of the smart factory.

The main driving force behind this development is the prospect of improving production efficiency and deriving cost benefits as a result. As a by-product, as it were, many of the effects that result have a positive impact on the sustainability of production: if, for instance, less energy is consumed, or components are put to longer use.

Shifting sustainability from a marginal to a central position

In the "AutoPilot" project funded by the German Federal Ministry of Education and Research (BMBF) (project number 02J21E004), an interdisciplinary consortium has since May 2022 been researching the use of available data for sustainability purposes. The focus is on the development of a fully integrated concept for recyclable production equipment: from the standardized development and integration in an adaptable manufacturing cell to recycling and/or reutilization.

To this end, a digital exchange platform is to be created between production and suppliers of production equipment, and a corresponding "Equipment-as-a-Service" (EaaS) business model established using this. In addition to EDAG Production Solutions, other project partners are WZL (RWTH Aachen), Ligenium, Stackpole, eVolution, Seeburger, Innoface and Capgemini. The project is due to run for three years, ending in April 2025.

All life cycle phases at a glance

By focusing on sustainability effects, it is possible to discover a great deal of potential for improving efficiency in industrial production. The life cycle of a production plant can be divided into the following four phases, each with its own specific opportunities:

- Preparation phase

- Planning and engineering phase

- Production phase

- Post-production

In the preparation phase, the foundation is laid for sustainable data usage. This involves a professionally organized data structure that makes for the easy access of data and information which is provided in a comprehensible manner. Questions relating to the (standard) formats used and to the data sources and their integration into a shared data room also need to be clarified.

Digital factory methods are used in the planning and engineering phase. This phase involves using digital models, methods and tools to develop an optimal digital plant concept that is as technically mature as possible and has been validated before a real-world production plant is built. This means that optimizations can already be carried out by means of simulation, and virtual commissioning can be prepared. In addition, it is also important to prepare for the use of new technologies such as AI, and to integrate the interface with building planning (technical building equipment planning in particular here), so that flexible adjustments can also be made at a later date.

In the production phase, networking the machines and systems along a "digital backbone" ensures improved communication and consequently also raises the efficiency of work along the value chain. The focus here is on improving overall equipment effectiveness (OEE) through the three factors of availability, productivity and quality. All three can be optimized by the systematic collection and evaluation of data, and, especially in terms of their sustainability, can also be influenced.

Data collected throughout the life cycle is of particular importance for the post-production phase, when, for example, decisions have to be made regarding the "second life" of the components: which of them can only be used in less sensitive areas, which are suitable for refurbishing, and which are only fit for recycling or disposal.

Data put to additional "green" use

The digital transformation of production towards the smart factory and the resultant data acquisition should therefore not only be used to improve operational processes, but can also serve as the basis for a consistent sustainability assessment to cover all life cycles: from a well thought-out basis in the preparation phase, through systematic front-loading for the planning and engineering phase and sustainable, zero-defect production, to concepts for "unretired" equipment in the post-production phase.

The results are not just helpful sustainability reports, but measurable cost benefits in consequence of greater efficiency and lower resource requirements: less energy and material are used, and components have a longer useful life and can be recycled more effectively.

If you, too, want to use your data pool to improve efficiency and increase sustainability, contact Dr.-Ing. Frank Breitenbach, Senior Technical Expert in Smart Factory Planning Methods, or Jana Speidel, Senior Engineering Automation Expert, for help and advice. More details of sustainability potential in the various life cycle phases can be found in the white paper "More Data for a More Sustainable Industry", which can be downloaded here.