Back in 2011, the German Federal Government launched a project called "Future Project Industry 4.0" , which was aimed at preparing industrial production for the future and giving companies the opportunity to play an active part in the fourth industrial revolution and add weight to establishing and promoting digitalisation in industry.

The intention behind Industry 4.0, or the 4th Industrial Revolution, was to replace outdated production methods with intelligent, networked production systems, in this way bringing about the intelligent fusion of manufacturing, product and IT. This enables companies to react flexibly to rapidly changing conditions and customer requirements, and to adapt and optimise their products and processes accordingly.

What are the advantages of the Smart Factory?

In all industries, the Smart Factory is the answer to the ever-increasing requirements and challenges confronting the manufacturing industry. Individualised customer requirements call for a high degree of planning accuracy and use of resources. Efficiency, productivity and quality are all expected to increase, though at the same time, costs are to be cut to a minimum. These targets are very difficult to achieve. Not for die Smart Factory, though.

Intelligent manufacturing can meet all these requirements, and has many more advantages over conventional production methods, including the following:

- Costs are already reduced in the planning and conception phase

- Later investments in hardware

- Optimised, agile, lean and accelerated processes

- Increased productivity along with reduced production time

- Production of individualised products in extremely small quantities at competitive prices

- Quick adaptation to new products and processes

- Reduced production costs

- Increased efficiency

- Quality assurance

- Fast reaction of production to changing or fluctuating market requirements

- Shorter delivery periods

- Transparent, automated order and supply chains

- Reduced time to market of new products

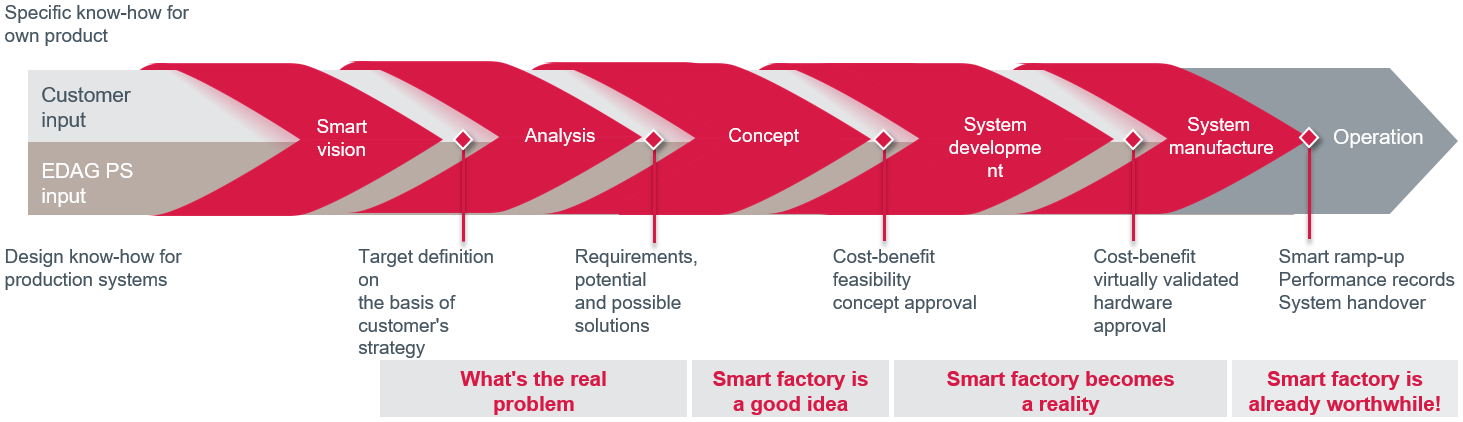

The 5 phases of the Smart Factory – the production development process at EDAG Production Solutions.

Years of production engineering know-how and a high degree of process reliability are our hallmark. Also, we have repeatedly optimised not only our technical processes, but also our tried and tested project management process, and over the years, have taken the countless standards and regulations for manufacturing processes and filtered out an essence that, in our view, combines the best standards from them all.

This has resulted in a standardised process model which provides transparent development steps that can be used to implement all Smart Factory projects and also the individual elements within the intelligent factory.

Our "5 phases of the Smart Factory" is therefore a standardized production development process that can be scaled and extended to include other subject areas, to guarantee our customers absolute transparency and safety in every phase.

The input and know-how of our customers are essential if the 5 Phase Model is to be successfully implemented. When it comes to your product and your manufacturing processes, you are the experts, and we need your knowledge so that we can combine it with our own expertise in the design of production facilities, in order to pave the way to an efficient Smart Factory.

The milestones in our process model are:

- Phase 1: The smart vision

Taking the customer's strategy as our basis, we develop an initial target definition. - Phase 2: Analysis

The customer's requirements are defined, initial ideas and possible solutions are shown and discussed, and potential identified. - Phase 3: The concept

At the end of the conception phase, concrete processes for the ideal approach are presented and validated; this process also includes a cost-benefit and feasibility analysis. - Phase 4: System development

The Smart Factory, with all elements from the concept, is constructed virtually - i.e. without hardware - and the cost-benefit analysis is again validated virtually. - Phase 5: Manufacturing the system

Your Smart Factory is now physically constructed and handed over to you after the smart ramp-up and performance verification.

Regardless of what industry you work in and whether you are planning a complete factory plant or only want to use certain parts of our portfolio, our experts will support you along the entire value chain, through to the realisation of your new production plant, and join forces with you to develop a cost-effective solution for your intelligent production. You can find out more about how we go about helping you to bring about your Smart Factory in our guide "5 Phases to your Smart Factory. EDAG's 5-phase model for the intelligent factory of the digital future". In addition, Andreas Friedrich, Vice President Realisation Smart Factory, can provide you with many exciting insights into the future of production. He looks forward to hearing from you.