Do you remember the commercial in which a sausage was used as a crash test dummy and driven into a wall? Did you wonder at the time who comes up with such ideas? The test was, of course, never carried out in this way, but the idea could have been ours. But we do test some rather curious applications. Sun cream that is rubbed onto the cockpit? Widely varying climatic zones and weather conditions? Kicks, bumps and blows to vehicle parts? Or simply wear and tear beyond their service life? We'll figure it out.

If the intention behind it were not so serious, you could also call the EDAG Accredited Test Centre, or “ATC Fulda”, a 4,000 m² dream playground for people with destructive tendencies. But when our engineers put cars through their paces, it doesn’t necessarily have anything to do with a desire to play.

The opposite is true: components and materials are tested to see if they are ready for start of production at the ATC Fulda. Using experiments that are absolutely realistic and reflect things that can happen in everyday life. After all, everyone is a little bit clumsy sometimes. And a modern car needs to be able to withstand life’s little mishaps – even if we are only talking about soft drinks or cosmetics - as much as it does wind, weather and wear and tear on tough roads.

Every relevant stress situation for modern vehicles can be tested

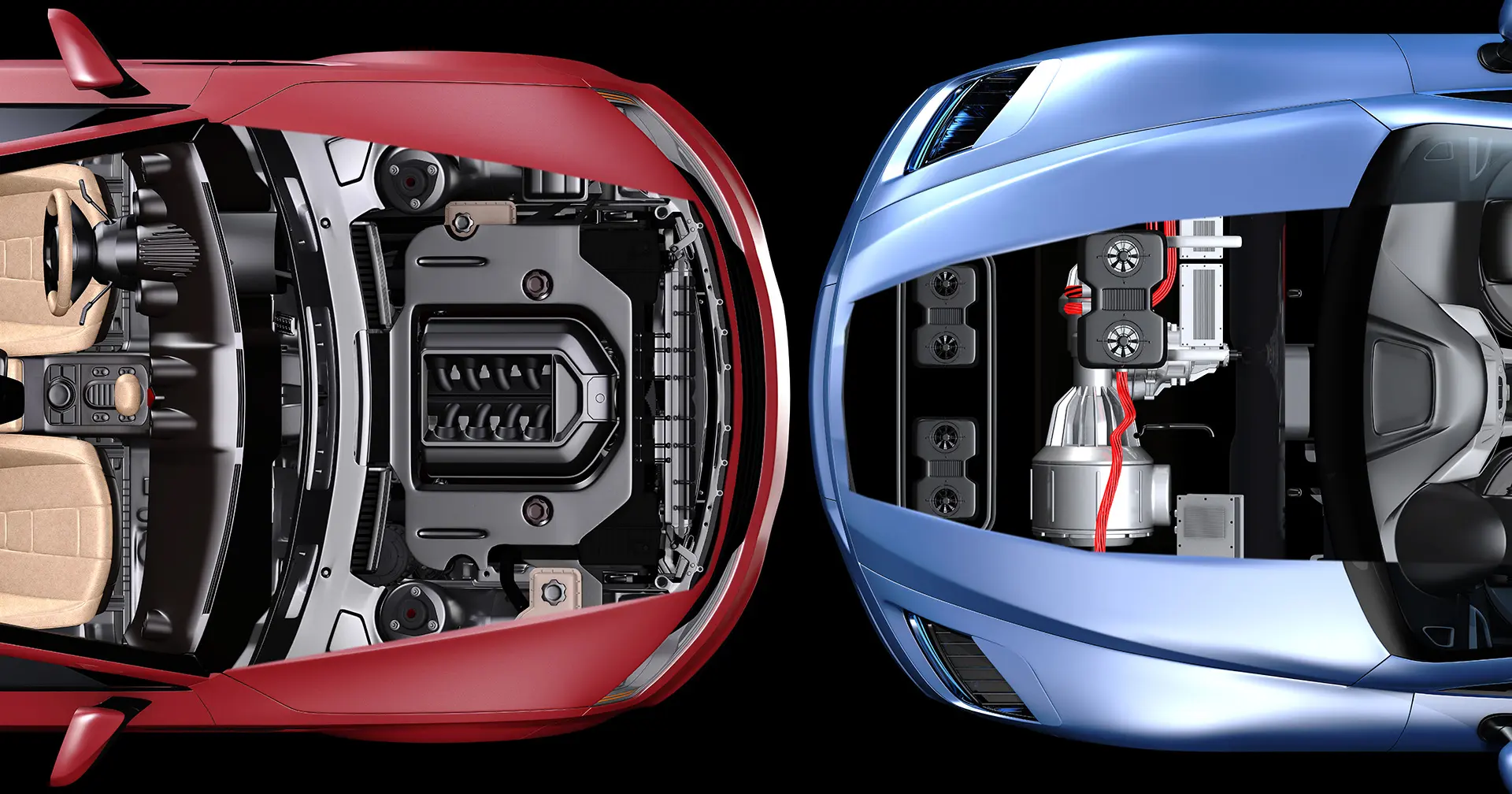

At the ATC Fulda, vehicle parts are constantly exposed to just these stresses. To do this, ATC Fulda has a unique and extensive collection of test setups, the like of which cannot be found anywhere else. From climatic chambers, mechanical, electrical or chemical tests and shakers, through to high speed cameras that register bending and tensile tests – ATC Fulda has a test solution for every stress situation relevant to the automotive industry.

Not until it is tested are the true qualities of a material revealed

Automobile manufacturers and suppliers, for example, can have materials cards that reproduce the performance level of their material combinations produced. In the process, materials are bent, compressed, twisted or pulled. Special cameras with a speed of more than 100,000 images per second quickly reveal a material's true qualities. Visual simulations from the field of Computer-Aided-Engineering (CAE) can also be validated with these tests.

From Siberian cold to desert temperatures: test setup creativity is called for

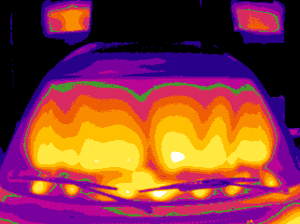

Electrical tests are another example from the ATC Fulda’s range of services. A current is sent through a conductor and it analyses what voltage drops, temperature changes or resistances occur in different stress situations. And if that is not enough to put electronic components through their paces, the EDAG engineers carry out the entire test in a climatic chamber. Because components need to perform to their utmost not only at room temperatures, but also in the coldest and hottest regions of the world, in constant downpours, under pressure changes, in direct sunlight or in electromagnetic fields. No wonder, then, that creativity and experience are called for when the test is being set up.

Electrical tests are another example from the ATC Fulda’s range of services. A current is sent through a conductor and it analyses what voltage drops, temperature changes or resistances occur in different stress situations. And if that is not enough to put electronic components through their paces, the EDAG engineers carry out the entire test in a climatic chamber. Because components need to perform to their utmost not only at room temperatures, but also in the coldest and hottest regions of the world, in constant downpours, under pressure changes, in direct sunlight or in electromagnetic fields. No wonder, then, that creativity and experience are called for when the test is being set up.

And this is why working at ATC Fulda means that rain, fog, earthquakes and lightning are all frequent and everyday occurrences.

Not only in the car do we make the most of our urge to play!

There are, of course, an infinite number of fields in which stress tests need to be carried out, including mechanical systems, flammability, water tightness, electrical systems, chemistry, etc. What would happen if you dropped the hairdryer in the bathroom one morning? Would you then have to go to work without first having done your hair? What happens if there is a power cut and your freezer defrosts? We can carry out all of these tests – and many more. Have you ever given any thought to what lighting is needed to withstand the severe weather conditions in the Gotthard Tunnel? We have.

Among other things, we test the following for our customers:

- Plastics and elastomers

- Textiles

- Coatings / laminations

- Electric / electronic modules

- Switches, connectors, contacts, leads

- Instrument panels, add-on parts

- Door side trims

Apart from the fact that our job is great fun, it also brings about many advantages for our customers: savings in terms of time and money, independent assessment, and much more.

Norbert Kamm, Head of ATC Fulda, would like to invite you to our large experimental playground, so that you can see for yourself that engineers do sometimes have to make a mess.