It is believed that the Chinese discovered the technique of lacquering 7,500 years ago. In fact, the oldest surviving recipe for a lacquer dates from the 12th century, and was composed of linseed oil to act as the bonding agent and sandarac as the pigment.

Paints and varnishes have always fascinated the human race. They were used to embellish people themselves or their surroundings. As a result of the industrial revolution and the invention of the car, paints and varnishes experienced a veritable boom, and new large markets were created for them. Spray guns were used instead of brushes, which significantly reduced drying and painting times and also greatly improved the quality of the paint finish.

The VR PAINTSHOP – a multifaceted and playful approach to virtual reality

Lacquers and paints are of great importance in our modern world. No matter what we consider, everyday objects, aircraft, ships or cars: they would be hard to imagine without some kind of colour.

Then as now, painting is expensive and harmful to the environment. Having said that, particularly in the automotive industry, a superior paint job can turn a vehicle into a unique and individual item. We have tried to achieve a balance, and combine sustainability, economic viability and design.

How? Put on a pair of VR glasses and experience painting from a virtual perspective.

Virtual reality and its efficient use im production engineering is just one of many major technological trends. In the painting process, material, technology and design come together.

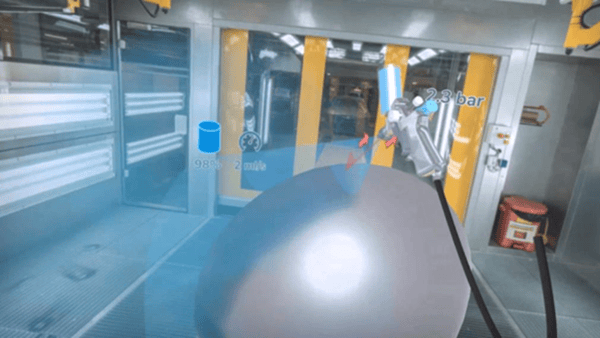

The visualisation specialists among our FEYNSINN digitalisation experts have developed the virtual training tool for car body painters: the VR Paintshop. Using VR glasses and a real paint sprayer, it is possible to train, test and experience the painting process in the virtual spraying booth. The integrated feedback system also generates a high degree of realism. This means the paint job can be completed very quickly.

This gives real-time feedback on all relevant parameters

- Paint thickness

- Spray angle

- Speed

- Distance

Compared to conventional training methods, gamification is used here. The user is constantly motivated and stimulated with high scores and challenges - until the perfect result is achieved.

Have fun painting and doing battle in the virtual spraying booth

Have fun painting and doing battle in the virtual spraying booth

The shine has by no means worn off

For some time now, the subject of "paintwork" has no longer been the sole concern of car body painters and paint specialists. The paint finish has become a high-tech product. With the simulation tool derived from the VR Paintshop by FEYNSINN, it is possible to reproduce the topcoat finish for exterior and interior coating in order to optimise possible implementation.

The application can be integrated into new and existing paint shops, and coupled with existing handling systems. Even variable speeds in different stations are no problem.

Monitoring the coats/layers of paint by colour feedback

Monitoring the coats/layers of paint by colour feedback

Bright paint colours turn green

It is now possible to spray and paint without paint mist, fumes and dirty hands, making it a clean matter for both the painter and the environment.

The absolute paint application is taken into account in the training simulation, and indicated by different colours. As a result, no paint is wasted, and reworking is only carried out where necessary. This is economical, and ensures consistently high quality.

With the simulation of painting processes and FEYNSINN's VR training tool, applications have been developed that are already being used successfully by international OEMs, BMW for instance. Our customers are particularly enthusiastic about the possibility of individualising the VR Paintshop. For example, customers' own components can be integrated, and even processes such as the painting of both sides are possible. The customer's own types of paint can also be integrated. There are almost no limits to the individual adjustments that can be made for customers.

However, EDAG Production Solutions and FEYNSINN support not only OEMs in the individualisation of their application requirements, but also companies from a wide range of other industries and sectors. They adapt the VR Paintshop to the special wishes of the customers. For example, there was an inquiry from a shipbuilder who wanted a flashlight on the paint spray gun to make it easier to paint tanks better from the inside. We have also received enquiries relating to painting wind turbines or applying aggressive cleaning agents, where the wrong dosage can quickly become a problem since overdosing can be harmful to health or attack the material of the component. Generally speaking, there are no limits to the possible range of applications for spraying substances.

The basis for all types of individualisation is the combination of VR Paintshop technology and the gaming technology used. FEYNSINN offers a complete package, which even includes the software, VR hardware and paint spray gun, laptop, case and of course support, installation and maintenance. And it still costs far less than many a competitor's product.

Would you like to try out our virtual spraying booth for yourself, or are you facing the challenge of making your paint shop more advanced and ecological? Or do you have an application that calls for special individualisation? Christoph Huber, Project Manager for Visualisation, is one of our virtual engineering experts, and will be glad to help you with any suggestions or queries you might have.