Robots have long been indispensable in modern production landscapes. Did you know that we have a cocktail party in the 1950s to thank for the invention of the industrial robot? Or to be more precise: the chance encounter there of the physicist Joseph Engelberger, who in his youth had devoured science fiction novels about robots, and the inventor George Devol? Back in 1961, the Unimate, as the two visionaries named their "baby", was already in use in the production lines at General Motors. From 1970 on, industrial robots also came into use in German car production. And even today, the ascent of the robot in production continues unabated. This makes it all the more important for optimal use to be made of these highly complex powerhouses, and for your staff to be thoroughly trained in how to handle them. FEYNSINN - an EDAG Group brand - once again merges the physical and virtual worlds to achieve this. But we have also gone one step further: we also teach the robot something new.

"It's like riding a bike. Not something you ever forget."

We all know this expression. And this is the starting point for our FEYNSINN colleagues: actively learning something that we can immediately put into practice is easier for us than a purely passive transfer of knowledge. Our intention is to use immersive media - virtual, augmented and mixed reality - to enable this active training to be carried out at a new, interactive level, in an environment that is virtual, but at at the same time combined with actual hardware. The advantage is that work processes can be practised again and again until they have been perfected. This provides the employee with direct feedback in real time as to whether he is doing everything right.

Digitalisation is accelerating the development of technologies at an unprecedented rate. If an international company wants to keep up with this pace and not run the risk of being driven off course, it will need to standardise its processes and not rely on stand-alone solutions. That also applies to training its employees. The more complex machines, systems and of course robots become, the more important it is to ensure continuous, cross-site training.

And where does the bike come in?

Quite simply: FEYNSINN focuses on learning through play and makes use of technologies from the gaming, computer and video game industry with its game engines. The VR Paintshop - a virtual training tool for the spraying booth, in which painting skills can be taught and tested using a combination of VR glasses and a real paint spray gun, has already been developed on the basis of this principle.

WITH XR-ROBOCONTROL, YOUR EMPLOYEES AND ROBOTS CAN LEARN EFFICIENTLY, BOTH FROM AND WITH ONE ANOTHER.

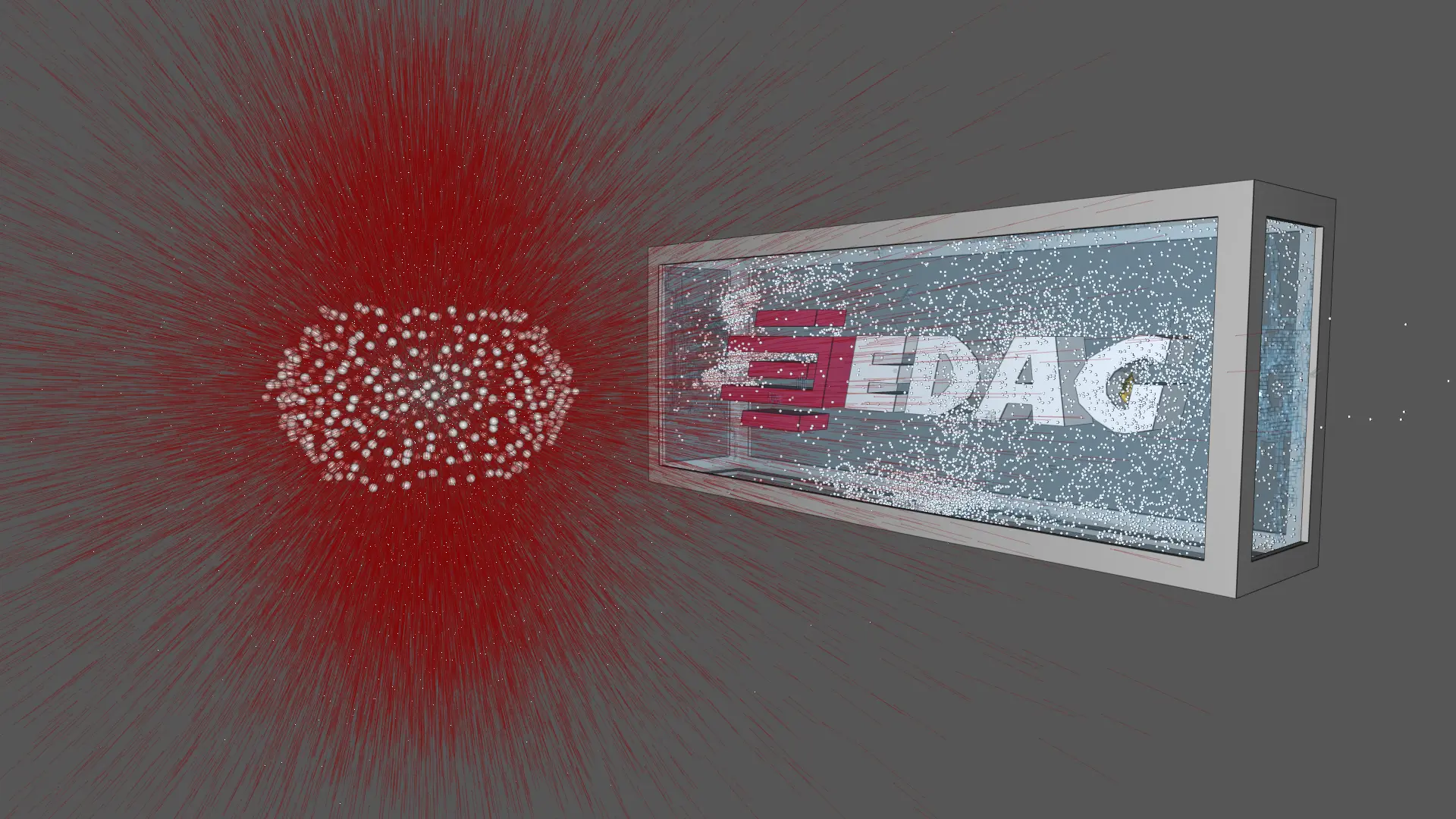

After the VR Paintshop had been developed, it stood to reason that this know-how should also be transferred to other fields, namely to the operation and programming of a robot. With Unity, a development environment, as our basis, we developed an interactive robot control application combining virtual and physical elements, namely mixed reality with the physical robot control panel - i.e. the digital data file is in the real environment, and the virtual robot is operated using the physical control unit.

The XR RoboControl is currently at the proof of concept stage. However, the FEYNSINN experts have a great deal more in the pipeline, and can also imagine incorporating customers' concrete use cases in future developments. Possible examples might be:

- Virtual staff training:

XR-RoboControl can be used for effective, location-independent and therefore cost-saving digital staff training in the use of robots. This will enable the functions, operation and also programming to be trained virtually in combination with the physical robot control unit. - Validation of the use of robots and the underlying programming:

Any information arising during the virtual training sessions is fed back into the system via the virtual reality data interface, as a result of which it is possible for virtually generated improvements and adjustments also to be carried out in the physical robot. In other words, the digital data file from the digital robot can be transferred to the physical robot, to test processes and functions before the physical system is installed. This means that digital tests can be carried out to see whether the robot sticks to safety zones, for instance, and improvements made very quickly, by means of intuitive programming if necessary. The information then programmed is subsequently transferred to a physical robot. - Individualisation in accordance with customer requirements:

Regardless of which operation you plan to use virtual, augmented or mixed reality for, we and our FEYNSINN colleagues will be happy to assist you with the implementation. We will work with you and the technical departments to develop a solution in a process involving several phases - from analysis and concept development, through to implementation and visualisation, in order to develop an application that presents even the most complex of topics simply and intuitively. In this way, it is possible to guarantee that training will be effective, even for employees without an IT background. When it comes to customer-specific requirements and realistic visualisation, with FEYNSINN, we can draw on a widespread network of experts, and are therefore in a position to provide complex projects from a single source. We will be happy to carry out a proof of concept for your project to evaluate whether or not an idea or a concept is feasible, and in this way quickly find a solution, for both small and larger budgets.

Admittedly, the technology behind all these possibilities is very complex. However, with the interplay of FEYNSINN's software and graphic visualisation know-how - which makes perfect on-the-job training opportunities possible - and the knowledge we have, which enables us to provide support in all matters relating to hardware, we are able to quite literally create the optimum interface between software and hardware. At EDAG, too, we already make use of virtual and augmented reality in what we have called our sofa collaboration, created for the virtual cooperation of international teams.

What sounds so simple is actually the perfect synthesis of a number of different technologies.

We work with software programmes such as Siemens NX and the Mechatronics Concept Designer (MCD) module, which enables us to use state-of-the-art 3D models and functions. As we use the design data of the robot - in our case a Fanuc robot - all the relevant information and requirements are available in digital format. In order to be able to use the virtual robot with a physical control panel, we need simulation software that will link the control panel with the CAD data. For the visualisation, we convert the design data into a generally readable data format, e.g. FBX for the game engine.

In addition to the geometrical data, we also need information on the robot's movements. To this end, EDAG and FEYNSINN joined forces to develop a plug-in that will extract this kinematic information from the design tool, convert it, and make it available to Unity. A further important element of our XR RoboControl system is the Microsoft HoloLens: a pair of wireless augmented reality glasses which, if integrated in a WLAN router, enables interactive 3D projections and information to be streamed.

The possibilities offered by mixed reality technologies are still in their infancy, and every day, our teams at EDAG and FEYNSINN are hard at work on the further development for potential applications. Chris Huber, Visualisation and Marketing Project Manager, helped to develop the XR RoboControl, and is looking forward to both the technical solutions and also to the challenges that the further development of the FEYSINN XR RoboControl is likely to bring forth.