Digitalisation is making production technologies and products increasingly complex. At the same time, the production processes necessary need to become faster, more flexible and above all more cost-effective, in order for resources to be used as efficiently as possible. At a very early stage, therefore, i.e. during its development or concept phase, it is important to find out whether your future plant will function according to plan, and whether when produced, your product will be defect-free. This is exactly what we do at the EDAG Technical Centre: carry out practical tests on all aspects of process validation, process engineering and robot technology, to provide the certainty that your processes are technically feasible and will really work. A Technical Centre is generally defined as a test station in which individual devices, machines or entire systems are tested in the laboratory under operating conditions. The process parameters determined in this way serve as a basis for subsequent processes and plants, and are incorporated in the calculations for the design of the real factory.

Joining technology laid the foundations for validation, optimisation and quality assurance in body manufacturing

The automotive industry has long been giving serious attention to the reduction of CO2 emissions and the reductions in vehicle weight necessary to achieve this. At the same time, production and ramp-up are required to be as efficient as possible.

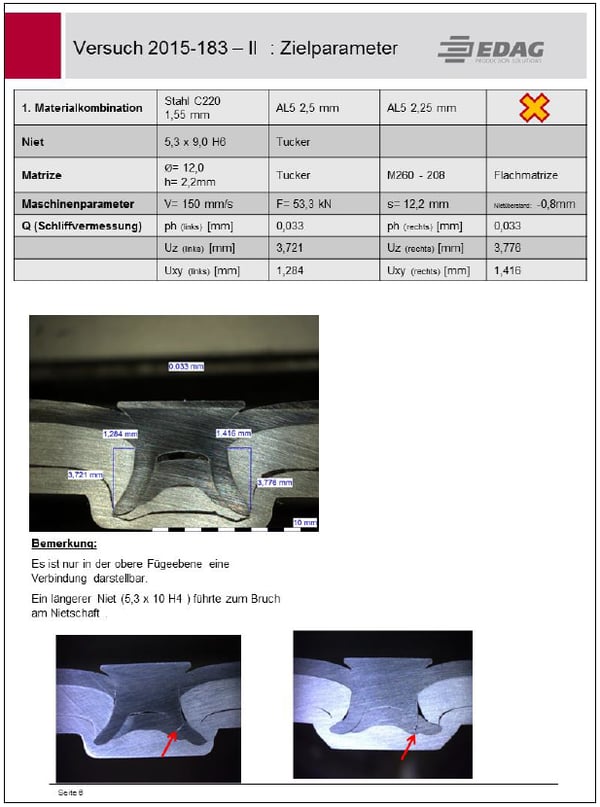

Depending on its size, a vehicle will have 5,000 – 10,000 join connections. OEMs are increasingly focusing on constructing lighter vehicles using innovative materials and processes. Modern lightweight construction must, of course, also meet the component and quality requirements of the automotive industry, while taking all relevant standards into account. Especially when implementing new material combinations, i.e. new metal combinations, it is therefore important to work out and validate the material parameters for the future production.

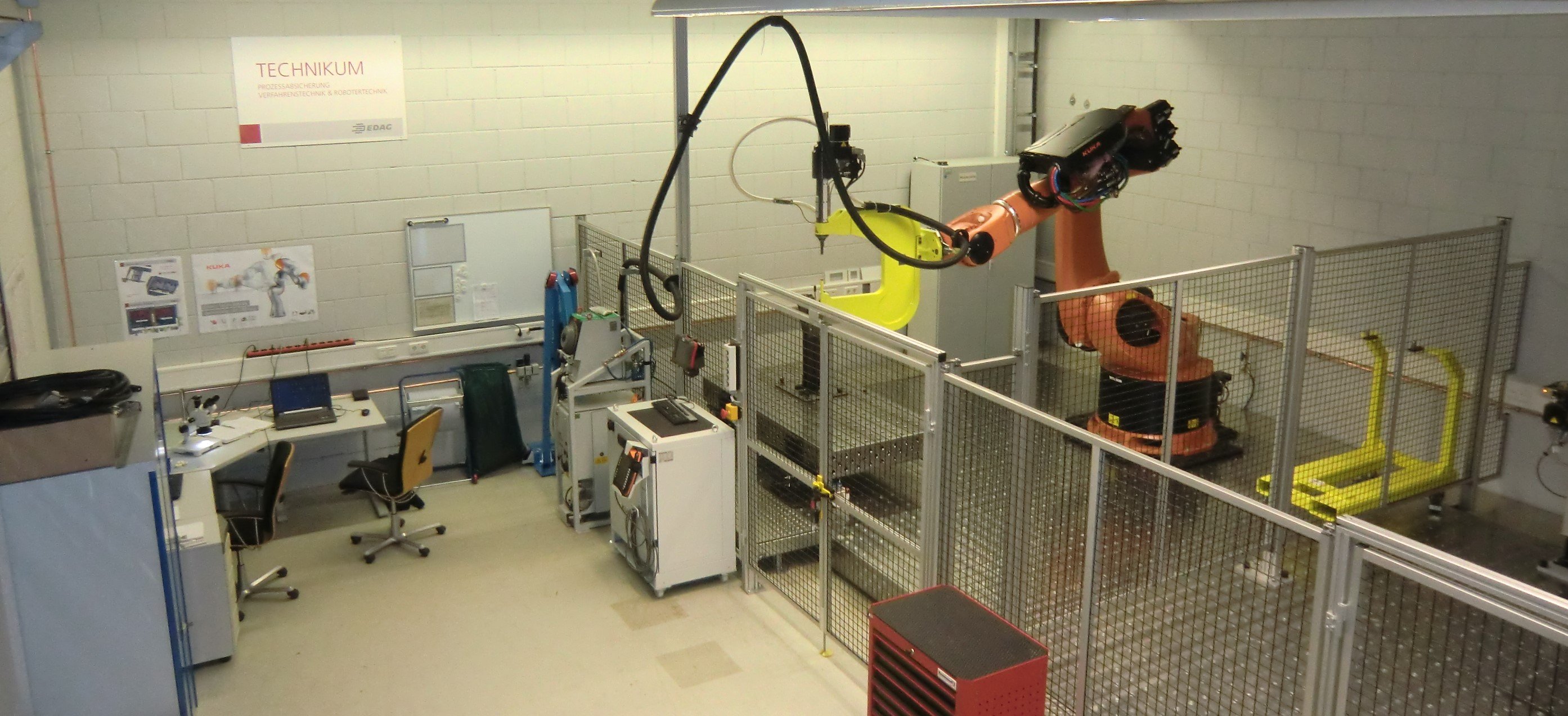

The original objectives of the Technical Centre, which was designed as a joining laboratory for the automotive industry, were process validation and the optimisation of joining technologies. With the aid of various tools, such as joining, welding and self-piercing rivet guns, but also wet cutting, grinding and polishing machines, or the use of robots, our tests always follow a fixed workflow: test preparation, test device, analysis. At the end, the customer receives detailed documentation - a test report - in which all the relevant measured data is recorded, i.e. which includes the process parameters of the individual test phases:

- Sample preparation

- Joining process

- Separation

- Embedding

- Grinding/polishing

- Cauterisation

- Microscopic examination

- Evaluation

The aim is always to test the various parameters, so as to obtain the perfect joining result in the end, and enable our customer's production ramp-up can be carried out quickly and without errors.

We back up theory with practice. Not just for the automotive industry, of course, but also for matters relating to special-purpose machine construction, general plant engineering, process engineering, and in particular to diverse robot applications, for instance in medical technology.

Especially in the early phase of production planning, i.e. in the concept phase, the validation of processes and technologies is essential for the correct planning and completion of modern production plants. Even at this early stage it is important to define concrete processes for the ideal strategy. For this reason, the concept phase is an essential part of the EDAG 5-phase model for the Smart Factory. Here, too, we also carry out hardware tests in addition to simulative and computational validation.

The EDAG Production Solutions Technical Centre consists of a team of experts for joining and roller hemming tests, but also experienced robot programmers who deal with the process validation of joining technologies, material validation processes, process optimisation and quality assurance.

This means that we are not just theoreticians and designers, but also have the necessary hardware in our laboratory to carry out tests under industrial conditions, e.g.

- Projects with individual test setups

- Mock-ups (presentation models to demonstrate functions)

- Tests under laboratory conditions in an industrial environment, also with the aid of robots

- Validation of new robot applications

For test setups, in addition to the equipment needed for the tests we carry out in the field of joining methods e.g. a Tucker self-piercing rivet gun with automatic rivet feed, we also use the robot technologies of various manufacturers for process validation. In our small robot laboratory, for example, we have robots with a load capacity of 6-14 kilos, but also industrial robots such as the KRC 240 or KRC 360 for heavy loads of up to 360 kg. Generally speaking, thanks to a flexible metal platform, the EDAG Technical Centre is also able to carry out individual test setups quickly and at any time, for instance tests with other hardware provided by the customer.

When it comes to the implementation of new production systems or a new production method by means of which you hope to optimise or automate processes, validating the design concept for your future production facility will guarantee its feasibility and prevent faulty planning. As the advice we offer our customers is completely independent, not only are we able to recommend the best technology available on the market for their application, but can also test the feasibility and load capacity of the design in a laboratory environment, and optimise it if necessary.

We do not, however, use only industrially tried and tested bought-in parts in the design, but often break new ground, by applying our own designs, especially in special-purpose machine construction, the repeatability and process reliability of which we then test under limited conditions, using as our basis the production equipment standards Uniserienstandard® developed in-house. So in technology development, not only do we deal with state of the art matters; we also like to think "outside the box" and look for new solutions that are not yet available on the market.

The EDAG Group is an international team of specialists. This means that they are always able to consult with other departments and draw on their expertise. While we in the Technical Centre deal with the validation of concepts for joining technologies in the preliminary phase, and with test setups for general technological developments, our colleagues in the ATC (ACCREDITED TEST CENTRE) handle quality assurance measures in the field of series production. They use other test laboratories, for instance climatic chambers, to carry out tests for defined environmental influences, test lights, perform tear tests, etc. They are an accredited test laboratory that carries out tests under a wide range of conditions including irradiation, climate simulations and gas release tests for clean room applications.

In contrast to our tests, which are carried out to determine the parameters for production, the focus here is on the parameters of the product.

Speaking of the product: we can of course also offer to carry out electric/electronic testing on new powertrains, i.e. eMobility. To this end, we have the support of our colleagues in the E-Laboratory.

Using the experience and equipment of our various laboratories, we can find the perfect solution for your project.

No matter what tests you have in mind for your production or product, we can offer you a wide range of test setups in our EDAG Technical Centre. Joachim Raff, our Chief Technology Consultant, will be happy to discuss with you any ideas you might have and how they might be implemented.