The success of the electric car rests on the question of whether adequate charging facilities can be created. Municipalities are expected to create even more charging stations, even more ultra-rapid charging points. Topping up batteries faster and faster isn't necessarily the only solution. The alternative is to "refuel" on more occasions – with a minimum of effort – namely wirelessly. EDAG has developed a solution for this that will help inductive charging to gather momentum.

How long will the battery charge last? This is a crucial question for drivers of battery electric vehicles (BEVs), and is closely followed by the next ones: Where can I recharge the batteries? And how long will it take? This is because the public charging infrastructure is unevenly distributed; Germany is still a long way from achieving true nationwide coverage, and this applies even more to our European neighbors. So more opportunities for recharging batteries quickly need to be created.

But this doesn't necessarily mean the usual charging stations. Attempts are being made to extend the range of trucks and buses with the help of overhead lines. A current collector on the roof of the family sedan or the box-type truck used by tradesmen is out of the question. However, plugless charging is still possible for vehicles of this type: by means of induction.

Wireless charging infrastructure

Inductive charging involves embedding a transmitter coil in the road and integrating a receiver coil in the vehicle. To charge, the driver drives his vehicle over the transmitter coil, and the batteries are automatically topped up. As with the wireless charging of smartphones, electrical energy is fed into the battery with the help of a magnetic field. The challenges with the automobile are the larger gap between the transmitter and receiver coils and the higher power needing to be transferred.

Within the context of the "LaneCharge" research project, EDAG, an engineering service provider in the automotive industry, has therefore developed and applied for a patent on a process for the inductive charging of battery electric vehicles which overcomes this restriction. The technology is particularly attractive for municipalities and infrastructure operators, as it enables them to provide a robust and interoperable charging infrastructure at low cost.

Vehicle takes control of the charging current

In the solutions used so far, the charging intelligence is located on the primary side, which usually means in the road. To date, a charging point has always had an electronic circuit on the primary side and one on the secondary side, and these communicate with each other in real time via WLAN. If, to optimize costs and resources, two or more transmitter coils are now to be operated concurrently on one of the electronics circuits on the primary side, this can impact the charging process if vehicles with different fill levels are charged at the same time. If, for example, the batteries in one car are charged to more than 80 percent, the charging current must generally be reduced. However, all other vehicles then also receive less energy, and the charging time is prolonged unnecessarily.

The newly developed control electronics means a paradigm shift for the inductive charging of battery electric vehicles (BEVs).

By contrast, with EDAG's solution, the control electronics are located in the vehicle. Although the electronic component in the road also supplies several transmitter coils, the charging power of the individual coils is adjusted to the individual energy requirements of the particular vehicle – a material contribution to the conservation of resources and cost reduction on the infrastructure side. This makes the technology economically attractive for municipalities and other infrastructure providers.

A further difference is that the traditional technology calls for real-time data communication via WLAN, to continually report data on the fill level, so that the controls can adjust the charging current in the transmitter coils. With EDAG's solution on the other hand, the charging intelligence installed in the vehicle decides autonomously how much energy it takes from the transmitter coil. There is therefore no longer any need for real-time communication. This cannot, however, be completely eliminated, because the vehicle has to check in to start the charging process and then check out again to stop it. Also, identification has to be possible, as this is the basis for billing.

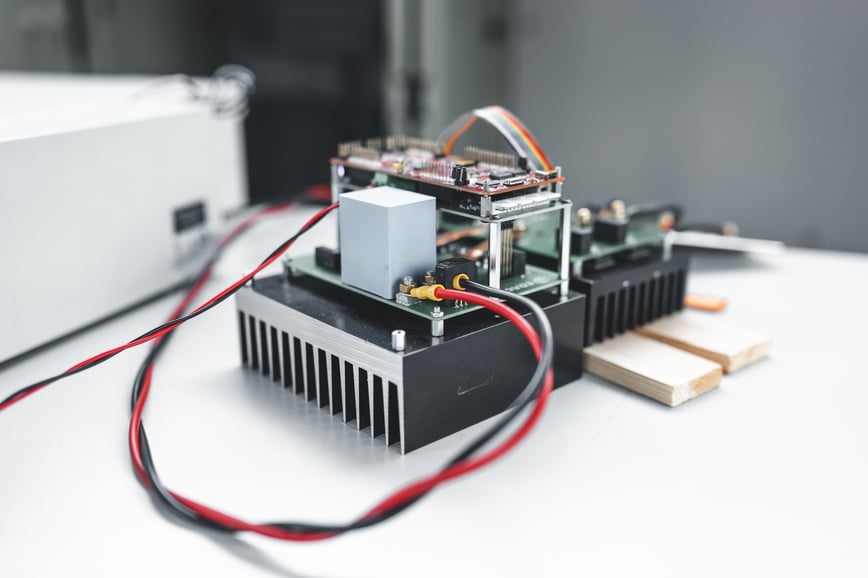

Tests are being carried out at the university's site, to determine the power of the induction coils embedded in the asphalt.

EDAG's task in the project is to develop the power electronics – both primary and secondary – and to integrate the individual modules into the vehicle.

The "LaneCharge" project is funded by the Federal Ministry for Digital and Transport with a total of 2.7 million euros as part of BMDV's Electromobility funding guideline. The funding guideline is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

Inductive charging has potential

The charging power in the project is limited to 3.6 kW, which places it in power class WPT1 (P≦3.7 kW). A ready-for-production solution might also reach WPT2 (P≦7.7 kW) or WPT3 (P≦11.1 kW) . According to the manufacturer, the Nissan model used in the project can be charged with a maximum of 6.6 kW.

Clearly, a largely discharged battery cannot be charged quickly with this kind of charging power. But the idea behind this charging technology is different: not waiting to charge until you have to, but charging whenever it is possible: in the parking lot at the municipal administration building, at the swimming pool, and at work. It is easier and more convenient to "refuel" frequently and in small quantities when the car is parked anyway than to drive to a charging station, possibly some distance away, to recharge the batteries.

In addition, EDAG's solution is suitable for more than just stationary charging, i.e. when the vehicle is stationary for a considerable period. As the vehicles in line at the cab stand are constantly moving one step forward, several charging coils are installed in a row in the waiting lane to enable semi-dynamic charging. This might also be conceivable at traffic lights, for example, where the short stop during the red phase could be used to charge the battery.

And last but not least, the inductive charging of vehicles is not restricted to road traffic only: Industry and publicly owned companies are already using battery-electric vehicles, such as low-floor vehicles, forklift trucks or mobile mowers. Here, EDAG's solution could simplify handling at charging stations, or perhaps even completely do away with the inevitable breaks for charging the batteries: by having charging coils in the routes usually traveled, so that the batteries are charged dynamically, i.e. during operation, and the vehicles are continuously available.

Jochen Rohm, Embedded Systems Development Engineer at EDAG, is supervising the "LaneCharge" project, and can provide further information on the solution developed by EDAG. You will also find detailed information in our white paper "Inductive Charging – but Smart", which presents the opportunities and added value of wireless charging for municipalities and users.