The development of the HOLON urban shows how HOLON combines innovative vision and its own technical implementation – together with strong partners. In the project for HOLON, the EDAG Group provided comprehensive engineering and production expertise – from vehicle development and production planning to prototype construction. The aim was to jointly transform the digital designs into a physical vehicle and optimize it with a view to later series production.The HOLON urban is an electrically powered shuttle that drives autonomously. It helps cities and regions to close gaps in their public transport networks. Cost-effectiveness is a key consideration for customers. That is why the development of the HOLON urban was geared towards industrial series production from the outset.

In the HOLON urban project, EDAG was entrusted with the construction of the prototypes and the design of the production facilities. This enabled the departments to work closely together. Requirements that arose during the construction of the prototypes could be fed back directly to the development department. Conversely, the changes were incorporated directly into the plans for series production.

The technical structure

EDAG's testing and vehicle construction department was responsible for implementation, supported by the production of handmade components in model construction. A frame had to be created in accordance with the specified design. In collaboration with sister company EDAG Production Solutions, fixtures were developed in which assemblies were mounted and checked for compliance with the specified dimensions in an initial quality control process.

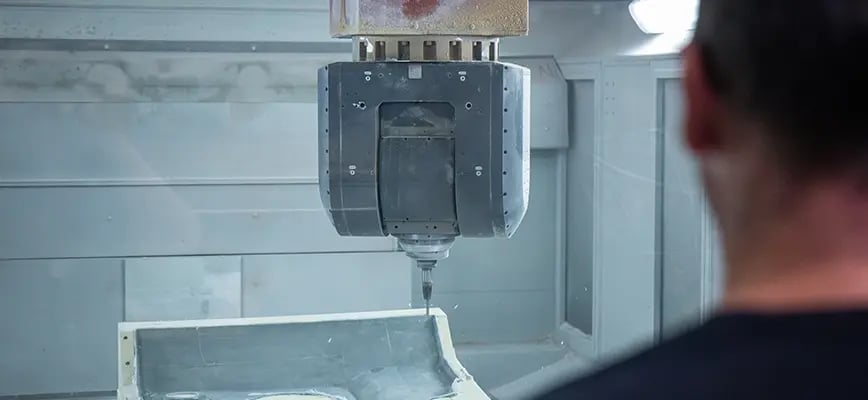

The finished body shell was coated with cathodic electrocoating. This was followed by the first integration steps, such as the installation of the wiring harness and the pre-assembly of the axles. For the exterior, the EDAG specialists developed complex, double-shell free-form components with the corresponding exterior contours. These were manufactured entirely from glass fiber reinforced plastics (GRP) using classic laminate construction methods and processed and trimmed using state-of-the-art CAD/CAM technology. One of the challenges was to achieve the dimensions and tolerances in the vehicle assembly with component precision.

Dynamic development

In the course of the project, optimizations and adjustments were made to the development process in order to gradually refine the vehicle, take technical requirements into account, and create a basis for subsequent series production.

Another challenge was securing the technical components. This was done with future series production in mind. Large front and rear hatches ensured accessibility, but it took several iterations before all requirements could be satisfactorily met.

Space for passengers

The basic design of the interior was specified by the HOLON designers with a so-called lounge seating arrangement. EDAG used prototype manufacturing processes to produce the interior components.

Component management

As is usual with innovative projects, opportunities for optimization arose during the development process in terms of component selection.

EDAG took over component system development at the outset, i.e., all data management between the partners involved. Based on the parts list from the development department, this involved comprehensive supplier and component management, including logistics tracking with quality control and on-time delivery. HOLON later took over data management with its own database.

Efficient communication across all trades

This made it all the more important to have a functioning and efficient build issue management system that could be used to systematically identify, evaluate, and implement optimization potential. This is where the close integration under one roof had a positive effect, promoting cooperation and solution-oriented thinking: Those responsible for prototype construction were able to coordinate directly with their domain leads from Vehicle Engineering and the customer in order to quickly arrive at solutions.

The customer benefits twice over: not only does coordination become faster and more efficient, but insights are also shared between departments, so that production planning, for example, benefits from the lessons learned in prototype construction.

Conclusion

The prototype and model construction department at the EDAG Group is characterized by a high level of technical expertise and a comprehensive service catalog. The development of the HOLON urban shows how technical expertise and innovative visions from HOLON, in close cooperation with strong partners such as EDAG, lead to successful project results. If you also have questions about the implementation of vehicle projects, please contact Michael Rittger, Claudius Höhl, or Udo Röbig from the Models & Vehicle Solutions division of the EDAG Group. Or download our white paper "Greater efficiency in the construction of mule cars and related development steps," which provides details on the EDAG mule car concept and the advantages of integrated development.