Swimming pools cost money - and not just because of the staff. Water treatment and air conditioning make maintenance expensive for local authorities. But are these often high costs even necessary to meet legal requirements and ensure safe operation? In the past, calculations were based on normative specifications and empirical values. Another approach is to completely recreate both the water basin and the interior spaces as a digital twin and run through flow simulations and possible changes. This is inexpensive, fast and can significantly reduce operating costs. In addition to the flow analysis, the acoustics in the interior spaces can also be simulated - long before the swimming pool has even been built!

SIMULATION OF THE BASIN HYDRAULICS: OPTIMUM WATER CIRCULATION FOR GREATER EFFICIENCY

"A lot helps a lot" is no longer up to date. In the past, pools were often oversized. Correspondingly high costs are caused by the strong circulation of the pool. There is little question as to whether less pump power is also possible.

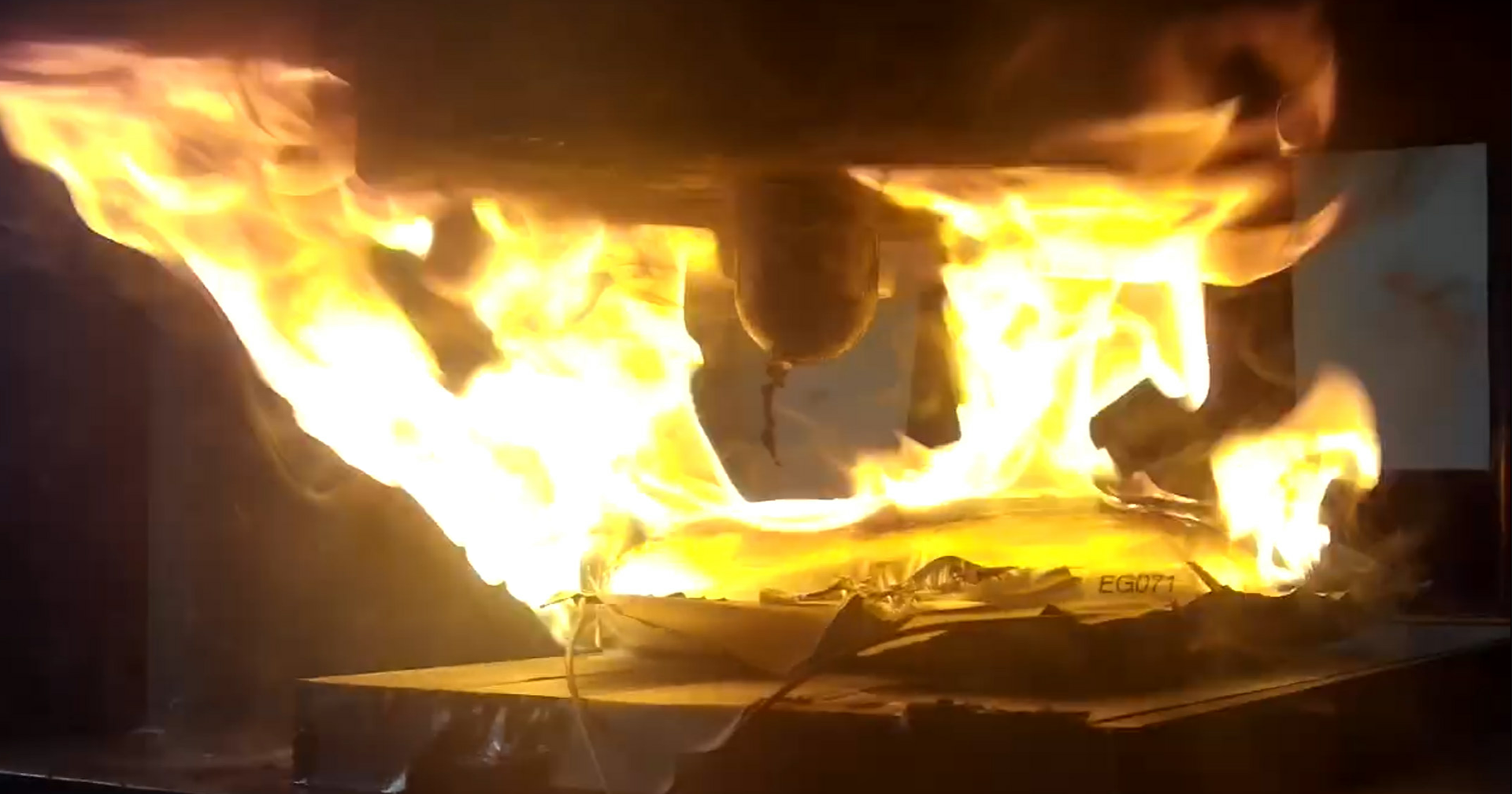

Coloring tests are carried out before commissioning. These are intended to check the pool hydraulics and ensure that the coloration is completed within a legally prescribed time. However, the water depths at which the water circulates and for how long (and is therefore not replaced and cleaned) is often unknown. Even extensive tests, in which the alignment and flow rate of the nozzles are specifically tested, do not always reflect reality.

Smart City approach: digital twin and simulation

However, there are now scientifically sound and proven calculation methods that can fully calculate and visualize water flows, even for complex pool geometries. These CFD (computational fluid dynamics) simulations take into account technical variables such as the water inflow and outflow volume, nozzle position and geometry, floor and pool geometry and much more.

Ultimately, the simulation creates a digital twin of the pool, which technically behaves in exactly the same way as the real pool. It can then be extensively modified and adapted. This allows engineers to determine in a very short time how fewer or more nozzles, improving the pool hydraulics and reducing the pumping capacity affect the retention time of the water in different areas and heights in the pool. An optimized volume flow also means that less water spills over the edge and thus even reduces noise pollution in the indoor pool. The reduction in water circulation saves operating and energy costs. The reduction in noise is a gain in comfort for bathers.

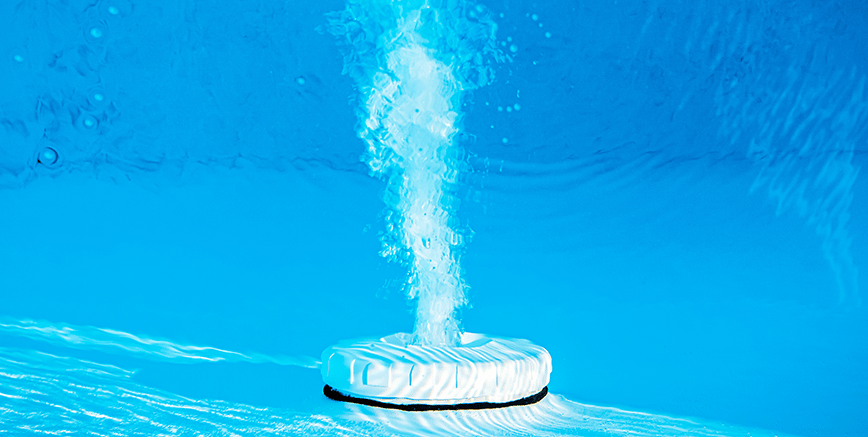

In addition to water circulation in classic pools, current channels, wave pools, water slides and water attractions of all kinds also play a major role in the bathing experience. A particle-based simulation approach is used here, which allows water movements to be modeled particularly realistically. This allows effects such as wave formation, splashing behavior or the design of water attractions to be assessed.

EDAG has the necessary know-how

There are currently hardly any engineers on the German market who carry out fully digital pool simulations. EDAG has been using flow simulations very successfully in the field of pool planning for several years. The pool operator mattiaqua has already commissioned the EDAG Group several times with CFD simulations to optimize the pool hydraulics, including for the indoor pool in Mainz-Kostheim. Based on the construction plans and an on-site evaluation, the pool could be fully digitized and then simulated.

Fewer jets and better circulation

The simulation showed that in one pool area, despite numerous nozzles at the edge of the pool, there was a larger vortex in which the dwell time of the water was longer than in other pool areas. This vortex was not only superficial, but also continued into deeper layers of water. The EDAG engineers were able to solve the problem by selectively switching off nozzles. This optimized the water exchange and prevented the vortex. After the successful simulation runs, the circulation of the water was significantly improved. A coloration test after switching off the nozzles confirmed the improved circulation.

Of course, local authorities cannot only carry out such simulations in pools that are already in operation. The calculations are particularly useful for new builds, as they help to avoid costly oversizing. Architects can use to optimize the pool geometry and jet arrangement before construction begins and reduce costs during construction and ongoing operation.

Advantages for pool operators

Simulation has numerous advantages for pool operators like Kostheim, especially when construction is still at the planning stage. These are:

- savings on initial and subsequent construction costs

- lower, optimized number of required jet

- exact pump performance without oversizing

- no subsequent corrections to the pool design

- no need to close the pool for flow and dye tests

- savings on ongoing operating costs

- minimized electricity costs for ongoing operation

- no subsequent increase in the required pump capacity

- sustainable operation: reduced energy consumption while maintaining consistent water quality

SIMULATION OF INDOOR AIRFLOW: OPTIMUM CLIMATE IN SWIMMING HALLS AND SHOWERS

Not only the water, but also the air flow in the indoor pool plays a decisive role for operators and bathers. Indoor swimming pools and shower rooms in particular place high demands on ventilation and air conditioning due to their special climatic conditions. High humidity, temperature differences and the distribution of pollutants such as chloramines can significantly impair air quality. At the same time, energy efficiency and comfort are key aspects, as inefficient ventilation systems can cause high operating costs as well as unpleasant draughts or damp problem areas.

Challenges in swimming pools and shower rooms

Water is constantly evaporating in indoor swimming pools, which greatly increases the humidity. Without targeted air circulation, condensation problems can occur on walls, windows or ceilings, which encourages the formation of mold. Condensation can also lead to long-term structural damage by attacking materials or causing corrosion.

Thermal comfort also plays an important role. Bathers should not feel uncomfortable due to cold draughts or stuffy, humid air zones. The formation of chloramine vapors can also have a significant impact on air quality.

These problems can only be avoided by effective air routing, which should also be operated with the lowest possible energy consumption.

ADVANTAGES FOR BATHERS AND OPERATORS:

CFD simulations make it possible to precisely analyze air flows, temperature distributions and humidity conditions - a level of detail that would be impossible to achieve with conventional methods, or only with considerable effort. This leads to the following advantages:

- Improved air quality through targeted air routing

- Avoidance of draughts

- Energy savings through optimized ventilation systems

- Reduction of mold and problems

SIMULATION OF ACOUSTICS: pleasant background noise for bathers

The acoustics in swimming pools are often underestimated. Large, tiled surfaces lead to strong sound reflections, which can result in an unpleasantly high noise level for bathers and staff. Added to this are noises from water circulation, ventilation systems and visitor activities.

Acoustic simulations can be used to analyze and specifically improve sound propagation in the interior. Sound-absorbing materials, modified room geometries or optimized ventilation systems help to create a pleasant acoustic environment.

ADVANTAGES FOR BATHERS AND OPERATORS:

- Reduction of the reverberation level for a quieter atmosphere

- Targeted placement of sound absorbers to minimize noise

- A more pleasant bathing experience for guests and a more relaxed working environment for employees

EDag offers the complete package for swimming pool simulations

With these three simulation approaches, the EDAG Group offers a complete package that covers all relevant flow and acoustic processes in the swimming pool. This not only enables considerable savings in construction and operation, but also ensures a sustainable and pleasant environment in swimming pools. Integrated digital planning makes swimming pools more efficient, more comfortable and more economical.

Further information and downloads

Would you like more detailed information on our digital flow twin? Then do not hesitate to contact Matthias Gaubatz, Head of CAE & Vehicle Safety! We will provide you with a detailed comparison.

Our white paper "Cost-efficient pool development with simulation technology" provides in-depth and highly technical explanations on how to optimise swimming pools.